You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Offered Service for Amiga 4000 3000 2000 1200 600 A3640 A3630 capacitor, SIMM socket, HDD&FDD port repair or replacement

- Thread starter tbtorro

- Start date

- Replies 571

- Views 175071

Please check my thread https://www.amibay.com/showthread.p...ills-expertise-on-Apollo-1230-mk3-accelerator

P.m sent for details on cost.

Hi, you have my replies by PM

My a1200 needs a recap. PM sent.

You have my answers via PM.

My a1200 needs a recap. PM sent.

A1200 motherboard was received from ozymandias.

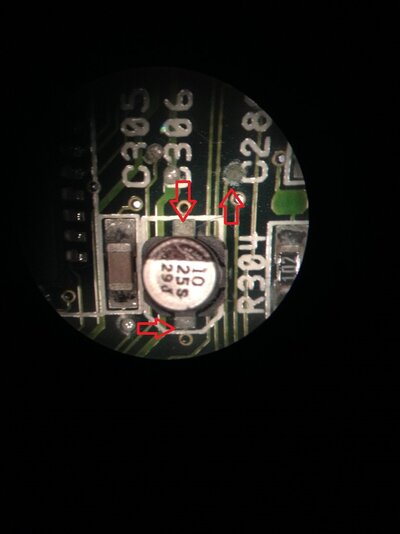

Some updates on Lechuck's Apollo 1230, I was able to take a look today, and there was a number of problems. As some of you may have read it on Lechuck's thread, the original symptom was that no RAM was recognized in the card.

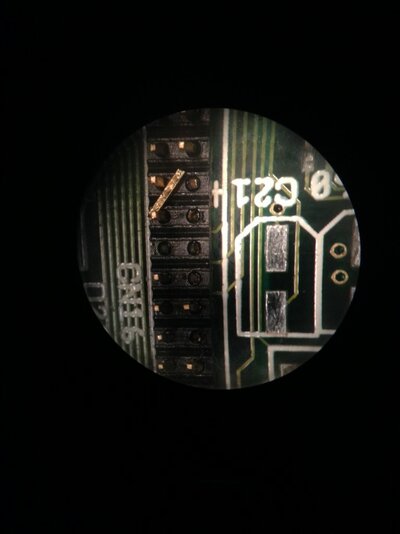

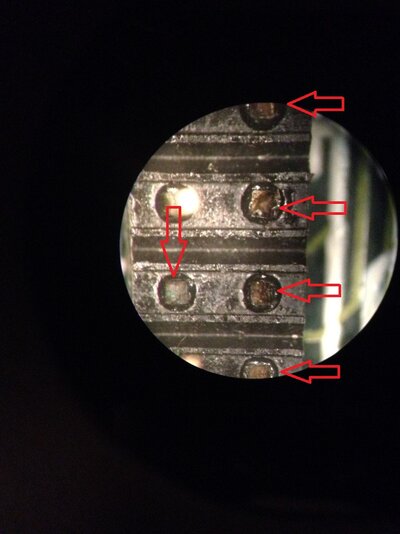

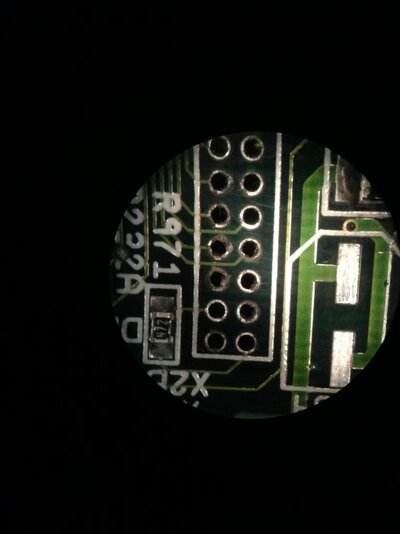

The first problem with this board was that some of the components (oscillator, jumper headers, and SIMM socket) was replaced by someone (not factory) and that person has done a rather poor soldering job.. Many pins were badly oxidized probably because of incorrect solder/temperature/tools were used. Worse yet, some pads on the jumper pins and the SIMM socket were warped and partly damaged. Luckily they all had continuity to the tracks so eventually after re-soldering/reflowing they were fine:

View attachment 86698 View attachment 86699 View attachment 86700

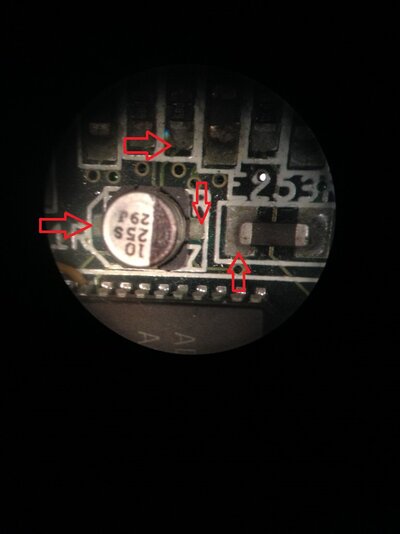

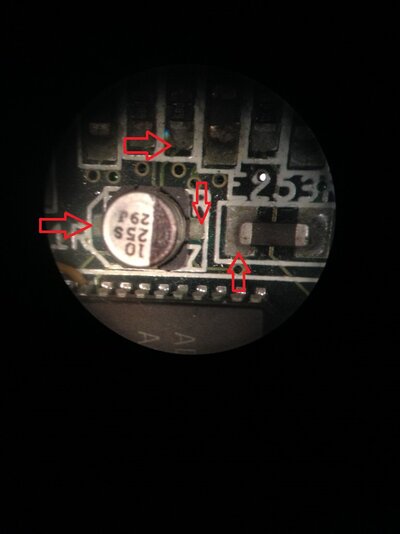

The next issue was that the SMD capacitor next to the jumpers has leaked and badly corroded the pads underneath. This was replaced. Furthermore one of the F257 buffer chips was faulty. I've decided to replace all 3 of them:

View attachment 86702 View attachment 86703

After some diagnosis, the next step was to add the SIMM sockets. At this point I was worried about the removed socket's pads (if some damage was done inside the layers) so I've decided to add the second slot first, (because those pads were still factory and undamaged) to make sure that the RAM logic is fine. So worst case at least one SIMM socket will be functional. After testing the RAM, I've added the second socket too. If you look closely you may notice how poorly the oscillator pins were soldered:

View attachment 86709 View attachment 86710

In the end both sockets were functioning fine. Here is the card happily buzzing away with 64MB RAM (which is the max). Usually I loop Elite II intro for a few hours as stress test for the heavy polygon graphics and music:

View attachment 86712 View attachment 86713 View attachment 86715

The first problem with this board was that some of the components (oscillator, jumper headers, and SIMM socket) was replaced by someone (not factory) and that person has done a rather poor soldering job.. Many pins were badly oxidized probably because of incorrect solder/temperature/tools were used. Worse yet, some pads on the jumper pins and the SIMM socket were warped and partly damaged. Luckily they all had continuity to the tracks so eventually after re-soldering/reflowing they were fine:

View attachment 86698 View attachment 86699 View attachment 86700

The next issue was that the SMD capacitor next to the jumpers has leaked and badly corroded the pads underneath. This was replaced. Furthermore one of the F257 buffer chips was faulty. I've decided to replace all 3 of them:

View attachment 86702 View attachment 86703

After some diagnosis, the next step was to add the SIMM sockets. At this point I was worried about the removed socket's pads (if some damage was done inside the layers) so I've decided to add the second slot first, (because those pads were still factory and undamaged) to make sure that the RAM logic is fine. So worst case at least one SIMM socket will be functional. After testing the RAM, I've added the second socket too. If you look closely you may notice how poorly the oscillator pins were soldered:

View attachment 86709 View attachment 86710

In the end both sockets were functioning fine. Here is the card happily buzzing away with 64MB RAM (which is the max). Usually I loop Elite II intro for a few hours as stress test for the heavy polygon graphics and music:

View attachment 86712 View attachment 86713 View attachment 86715

Last edited:

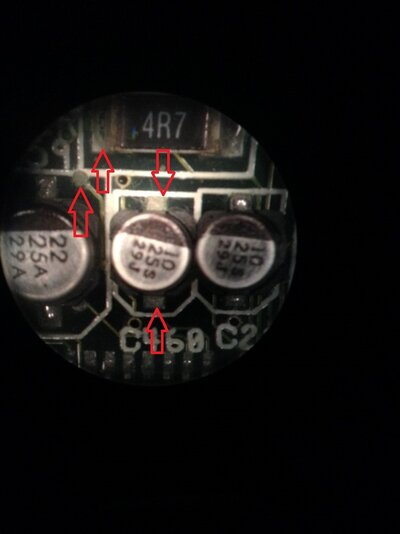

Work started on ozymandias' Amiga 1200 motherboard. Some work in progress updates:

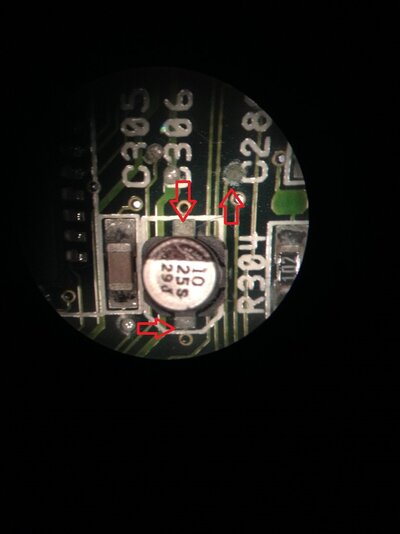

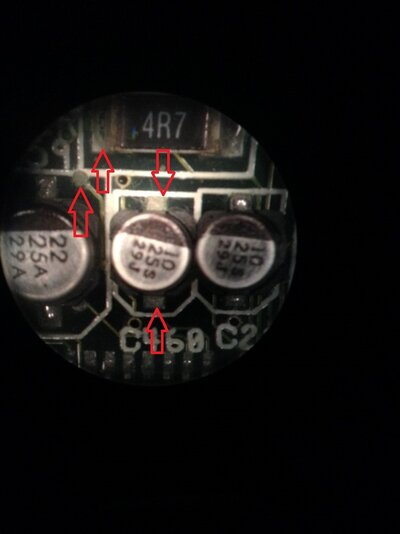

Removed all the old capacitors, looks like ozymandias' call to replace them was past overdue. About 5 capacitors has leaked and corroded the board and some components around them. Notice how grey and dirty the joints and the surrounding area look like. What happens is that the acid leaks out to the board and attracts dust and fluff particles that stick to the board. Luckily all pads and joints still had continuity so the damage will stop after cleanup:

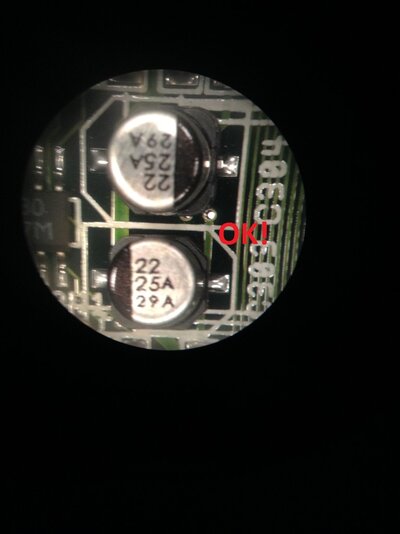

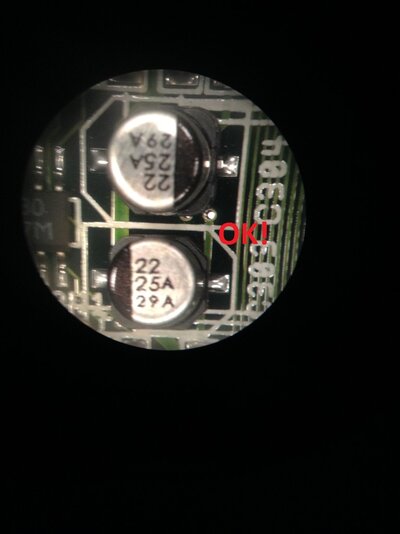

This is how an original (factory) healthy joint looks like, from the same board. Notice how clean the area around, and the shinny surface of the joint in comparison. However it's still not guaranteed that the capacitor is OK, only that it's haven't leaked yet:

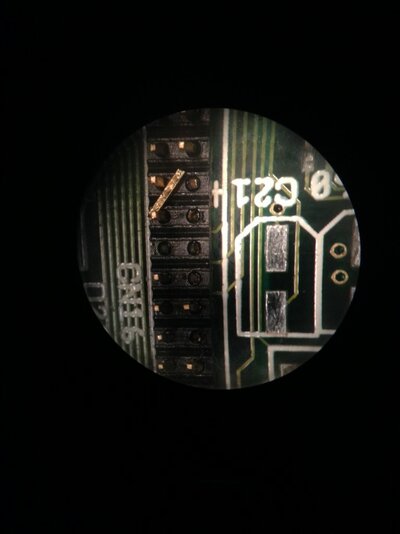

The next problem is that I've noticed that few of the pins of the IDE connector was missing. When I probed the rest, about 5 of them snapped right off with a light touch. Which was very surprising because the IDE pins can take a decent amount of force.

On closer inspection, I found that the acid from a leaked capacitor ate away the copper pins. Each pin sits in a little 'cup' in the plastic socket and the acid, once seeps inside this 'cup' will slowly work the base of the pin. This happens because although on the surface the acid can dry and become less corrosive, when it's enclosed in a semi-closed space, then it can work for a long time. The effect is similar to how teeth get a cavity: bacteria create acid between the tooth and gum, that slowly break down your tooth at the base.

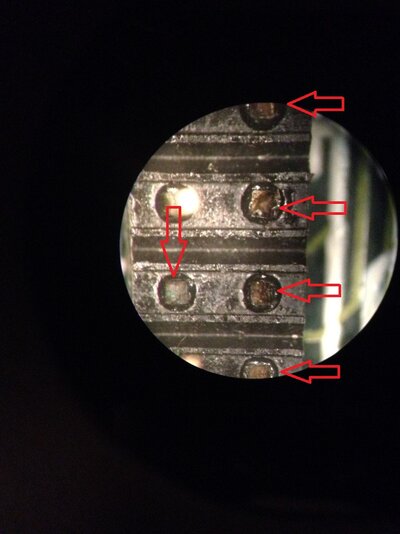

Notice how all the breaks are dirty/green/oxidized and not gold color as fresh copper should look like. On the last picture, that particular pin had a tiny bit of copper joining only in the corner, which was not enough to withstand even a light touch. I'll have to contact ozymandias to check if any pins remain in his IDE cable, because I could not find all the broken off pins. The exact same thing happened to this guy: Link This connector is definitely has to be replaced:

Removed all the old capacitors, looks like ozymandias' call to replace them was past overdue. About 5 capacitors has leaked and corroded the board and some components around them. Notice how grey and dirty the joints and the surrounding area look like. What happens is that the acid leaks out to the board and attracts dust and fluff particles that stick to the board. Luckily all pads and joints still had continuity so the damage will stop after cleanup:

This is how an original (factory) healthy joint looks like, from the same board. Notice how clean the area around, and the shinny surface of the joint in comparison. However it's still not guaranteed that the capacitor is OK, only that it's haven't leaked yet:

The next problem is that I've noticed that few of the pins of the IDE connector was missing. When I probed the rest, about 5 of them snapped right off with a light touch. Which was very surprising because the IDE pins can take a decent amount of force.

On closer inspection, I found that the acid from a leaked capacitor ate away the copper pins. Each pin sits in a little 'cup' in the plastic socket and the acid, once seeps inside this 'cup' will slowly work the base of the pin. This happens because although on the surface the acid can dry and become less corrosive, when it's enclosed in a semi-closed space, then it can work for a long time. The effect is similar to how teeth get a cavity: bacteria create acid between the tooth and gum, that slowly break down your tooth at the base.

Notice how all the breaks are dirty/green/oxidized and not gold color as fresh copper should look like. On the last picture, that particular pin had a tiny bit of copper joining only in the corner, which was not enough to withstand even a light touch. I'll have to contact ozymandias to check if any pins remain in his IDE cable, because I could not find all the broken off pins. The exact same thing happened to this guy: Link This connector is definitely has to be replaced:

Last edited:

Small update on ozymandias' A1200 board, the faulty IDE connector was removed and waiting for the replacement part (should arrrive this week).

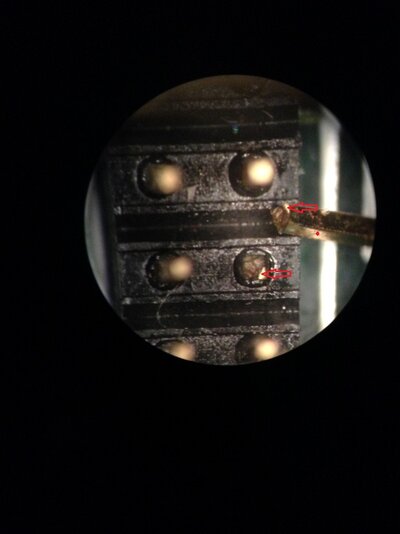

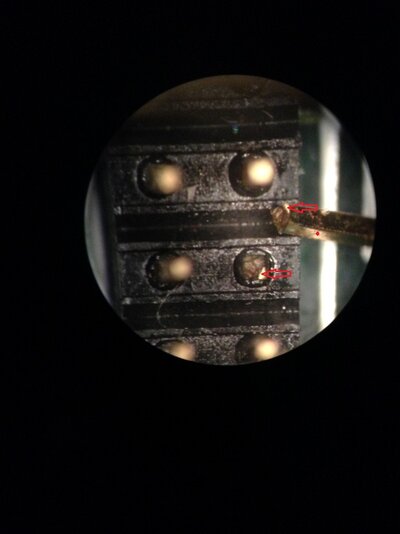

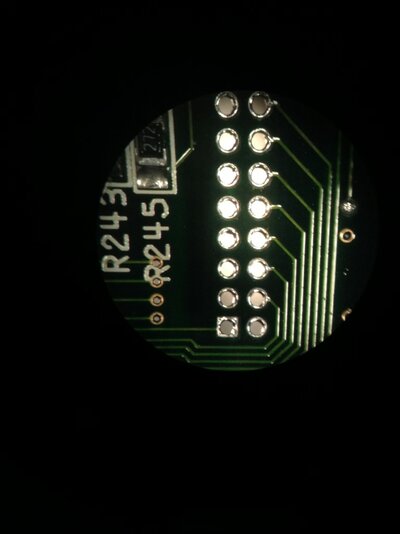

This is what I've found under the port, the through hole plates are badly corroded by the acid from the leaked capacitor next to it. The problem is that they are very difficult to clean up, because of the damaged and contaminated plates have very poor heat transfer properties. Good news is that all plates had continuity to the connecting tracks:

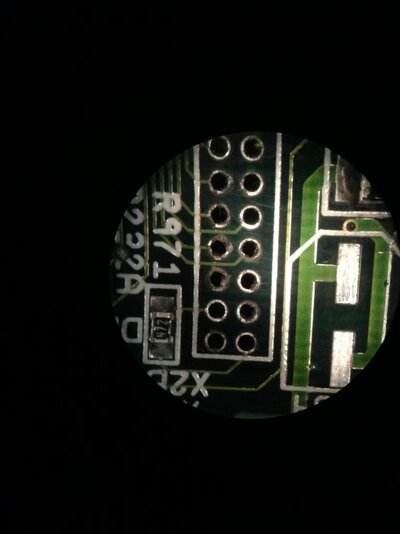

In comparison this is from the underside of the board of the same connector, healthy plates should look like this after rework:

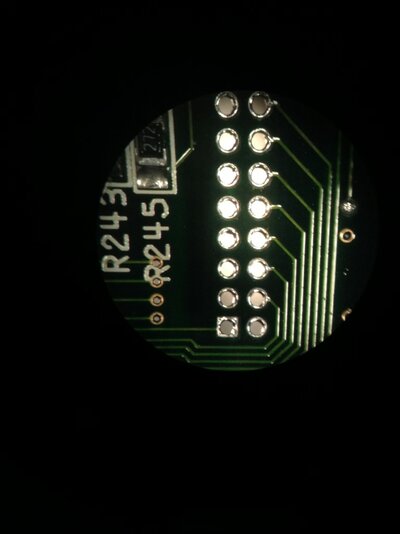

After the cleanup of the entire area. The top hole plates of the IDE connector are not perfect, but I did not want to re-heat them too many times, so this will have to do:

This is what I've found under the port, the through hole plates are badly corroded by the acid from the leaked capacitor next to it. The problem is that they are very difficult to clean up, because of the damaged and contaminated plates have very poor heat transfer properties. Good news is that all plates had continuity to the connecting tracks:

In comparison this is from the underside of the board of the same connector, healthy plates should look like this after rework:

After the cleanup of the entire area. The top hole plates of the IDE connector are not perfect, but I did not want to re-heat them too many times, so this will have to do:

Last edited:

Hi Tbtorro great work did you heat gun the IDE header off or remove each pin one at a time ?

I find the safest and easiest way to remove headers like this is to clip the pins on the component side, then remove (pull off) the plastic base *very carefully*, and then remove each pin one at a time using a normal iron and a tweezer. Another option is to use a de-solder iron with an automatic pump, but this takes longer so I only use that method if I want to save the component. I never use a heat gun for component repair because it's difficult to control what's gets heated and what's not, unless you have correct nozzles for each components.

Work complete on Lechuck's Apollo 1230, installed FPU + socket, shipping back on Monday

View attachment 87412 View attachment 87413 View attachment 87414

View attachment 87412 View attachment 87413 View attachment 87414

Last edited: