Hi folks!

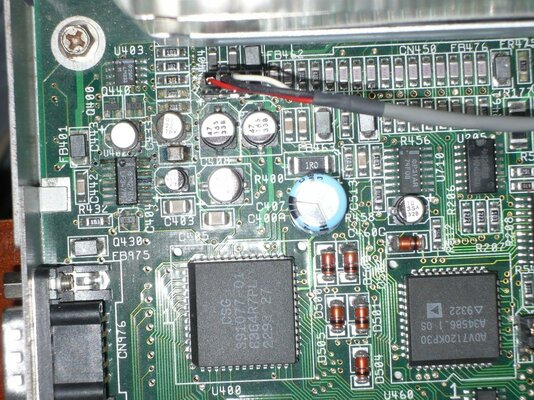

So, I'm the happy new owner of an a4000D, but have a problem. The machine boots up, displays, mouse works, etc. (didn't test audio). But, upon opening her up, I found a number of leaky caps. I've attached a snap shot of the audio circuit area, which is one of the worst areas.

I'm looking for some advice on how far to go in fixing this. I ordered a cap kit from Cosmos right away, but it will take a week or so for it to get here. In the meantime, my gut tells me to take a ton of pictures to document where everything goes, and to pull the old caps as soon as possible. Followed by liberal application of lemon juice, IPA, and gentle scrubbing to prevent further damage.

My question is around how much proactive cleanup I should do. Take, for instance, the cap just below C433, which has green fuzz on the solder joints. Is that just a scrub and neutralize? Or should that get a wicking of old solder, and application of new? Or a complete removal/cleanup/replacement? Likewise the resistors above C433.

Likewise the IC (LF347M) below C443, which really scares me. It looks like leads 1 and 11 are really bad off. Is that just a cleanup, or a remove/replace? Ditto Q400/Q440 above C443.

This area is, by far, the worst. The RTC doesn't work after some light battery leakage, but that area is nothing compared to this.

Thanks!

WhyreByter

So, I'm the happy new owner of an a4000D, but have a problem. The machine boots up, displays, mouse works, etc. (didn't test audio). But, upon opening her up, I found a number of leaky caps. I've attached a snap shot of the audio circuit area, which is one of the worst areas.

I'm looking for some advice on how far to go in fixing this. I ordered a cap kit from Cosmos right away, but it will take a week or so for it to get here. In the meantime, my gut tells me to take a ton of pictures to document where everything goes, and to pull the old caps as soon as possible. Followed by liberal application of lemon juice, IPA, and gentle scrubbing to prevent further damage.

My question is around how much proactive cleanup I should do. Take, for instance, the cap just below C433, which has green fuzz on the solder joints. Is that just a scrub and neutralize? Or should that get a wicking of old solder, and application of new? Or a complete removal/cleanup/replacement? Likewise the resistors above C433.

Likewise the IC (LF347M) below C443, which really scares me. It looks like leads 1 and 11 are really bad off. Is that just a cleanup, or a remove/replace? Ditto Q400/Q440 above C443.

This area is, by far, the worst. The RTC doesn't work after some light battery leakage, but that area is nothing compared to this.

Thanks!

WhyreByter

Attachments

Last edited: