protek

"Takai desu ne." -"Jinsei da."

I suppose this project has progressed to a point that warrants its own thread. In an other thread I've been going through my exploits with Autodesk 123D Design.

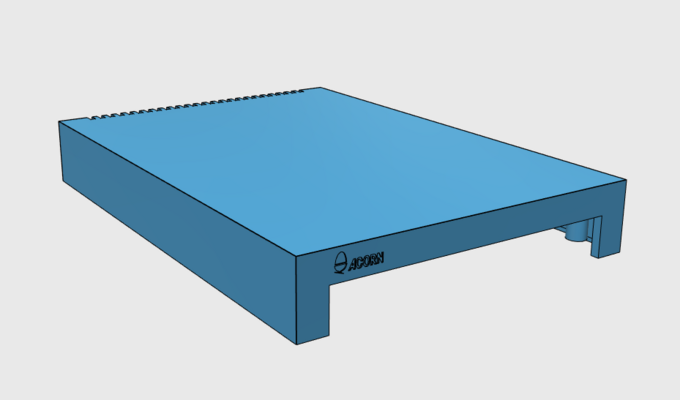

Couple of weeks ago I started designing an enclosure for a 3,5" floppy drive that would make it a proper external drive. I use external floppy drives with my Amstrad CPC6128, Spectrum +3 and BBC Master.

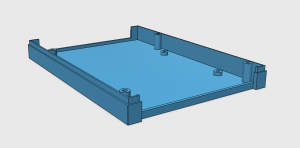

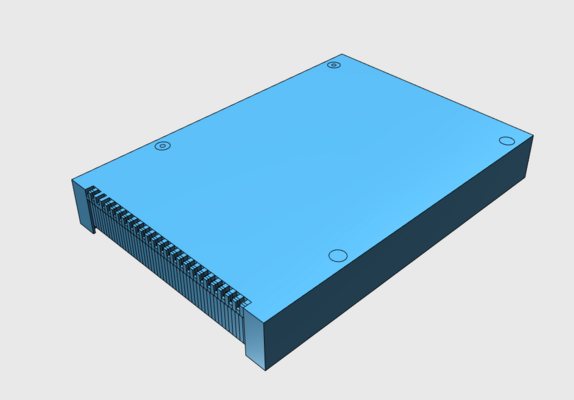

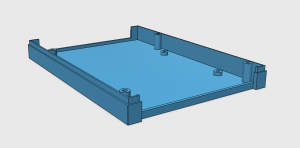

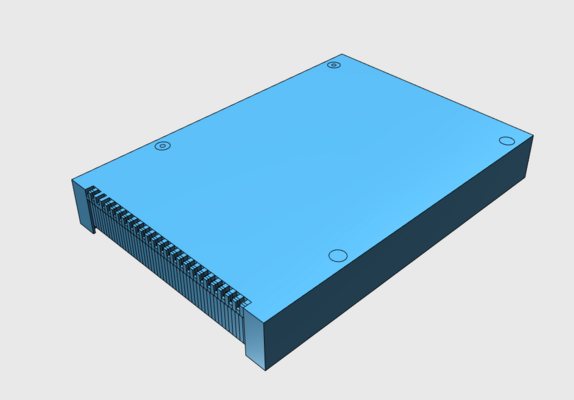

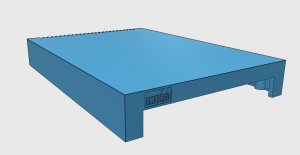

Here are a couple of pics of the first versions of the case.

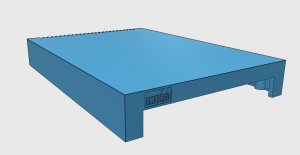

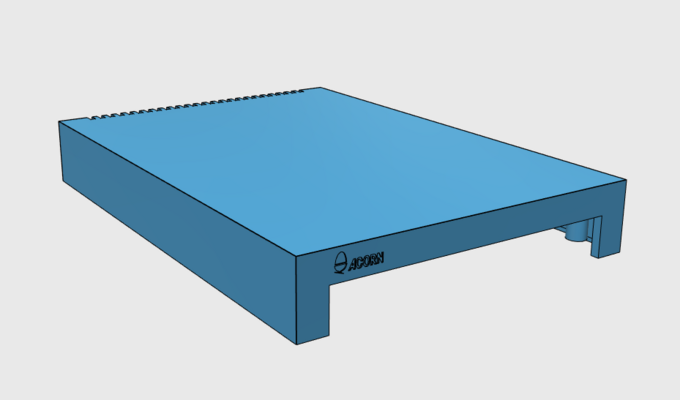

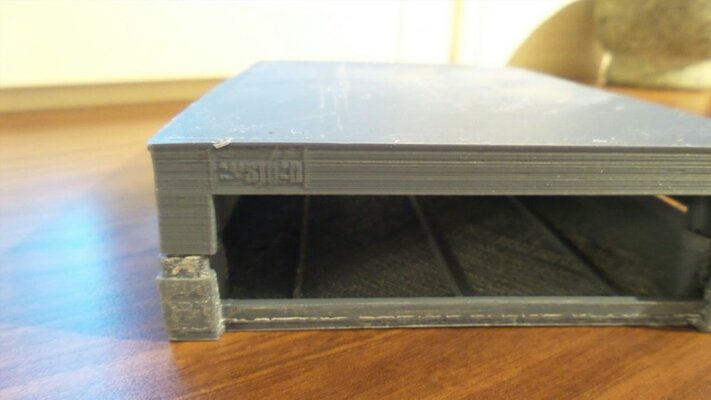

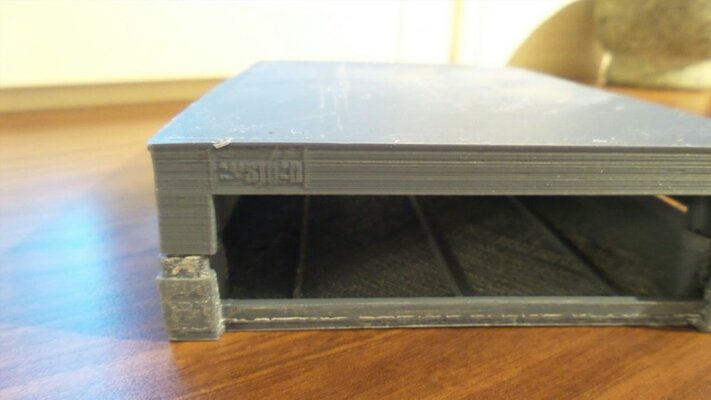

Yesterday I got a couple of pictures from a friend of mine who has access to a 3D printer. This is the first version.

As a printed piece this is quite large, which causes its own challenges to the material. ABS has a tendency to warp with such a big piece. Therefore HIPS was chosen as the print material for the item in pictures.

I've actually tweaked the model based on the results. One of them is to make the logo an empty space onto which the actual logo will be printed with a finer pitched nozzle to make it more accurate. The other was to leave more room for overlapping parts.

Stay tuned for more.

Couple of weeks ago I started designing an enclosure for a 3,5" floppy drive that would make it a proper external drive. I use external floppy drives with my Amstrad CPC6128, Spectrum +3 and BBC Master.

Here are a couple of pics of the first versions of the case.

Yesterday I got a couple of pictures from a friend of mine who has access to a 3D printer. This is the first version.

As a printed piece this is quite large, which causes its own challenges to the material. ABS has a tendency to warp with such a big piece. Therefore HIPS was chosen as the print material for the item in pictures.

I've actually tweaked the model based on the results. One of them is to make the logo an empty space onto which the actual logo will be printed with a finer pitched nozzle to make it more accurate. The other was to leave more room for overlapping parts.

Stay tuned for more.

Last edited: