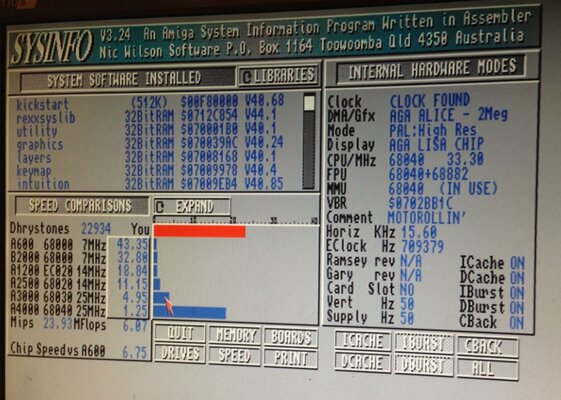

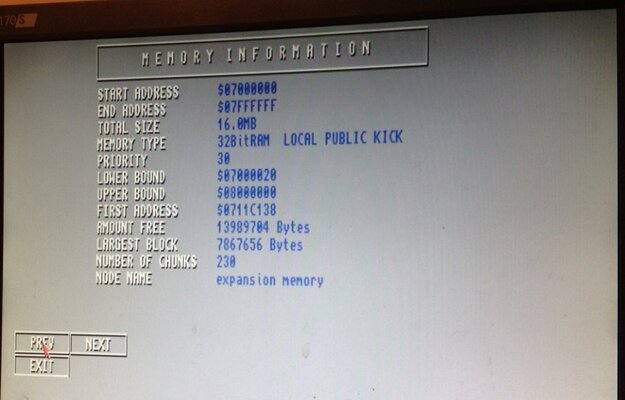

A few years back I picked up an overclocked '040 (A3640) card here for my A4000 (which had been shelved for awhile) and was excited to try it out; after installation I quickly noticed serious audio crackling and after a short while lost a channel. Opening the case for closer inspection revealed that the audio caps were starting to leak; cleanup was performed and I re-shelved it for the time being.

I researched my options and decided I really wanted to fix it myself, but knew I wasn't skilled enough to do it as my work had been limited to large through-hole and wiring. I wasn't willing to risk it as this is my childhood machine that I'd used for 3D animation, code and music for many years growing up and has a lot of sentimental value.

So I set off to watch YouTube tutorials and try to learn everything I was missing. Off and on for the past few years I've been buying and soldering random kits and watching as many videos as I could to try and reproduce the techniques properly. In particular I found inspiration with the work of Dave Jones (EEVBlog), Louis Rossman (Flux The Everything!), Big Clive and many amiga-specific soldering demonstrations.

A few days ago I was more than confident that I was ready to tackle the A4000; upon opening the case for the first time in a few years it was quickly evident that nearly every cap had leaked -- in particular all the 47uf caps were sitting in a pool of their own electrolytes; so I quickly swabbed everything up with alcohol and prepared to extract them all.

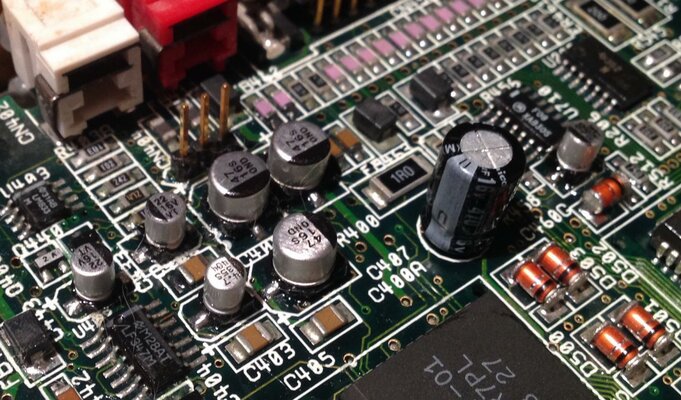

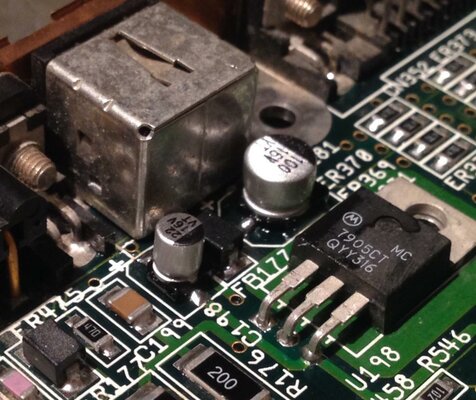

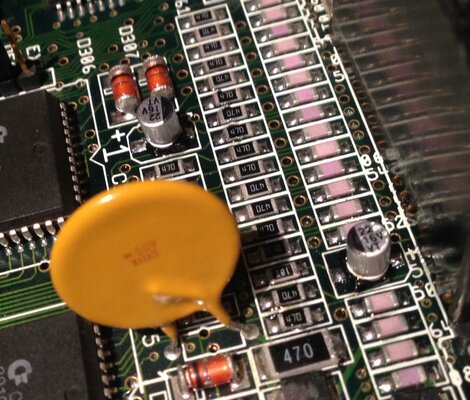

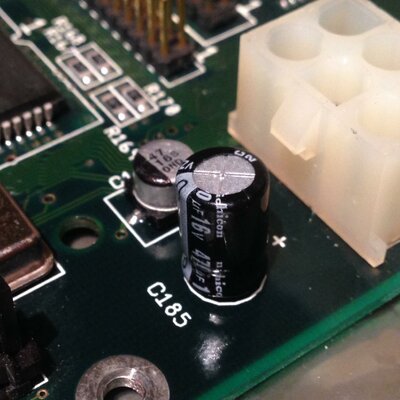

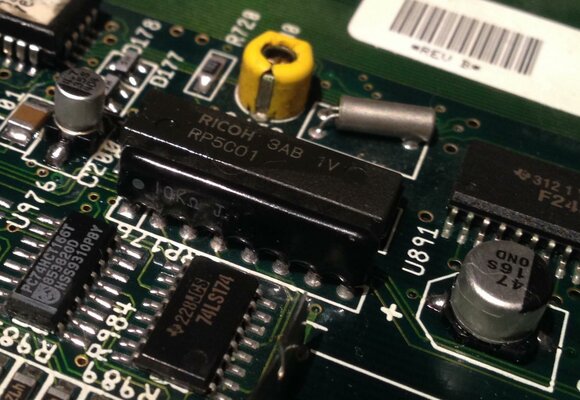

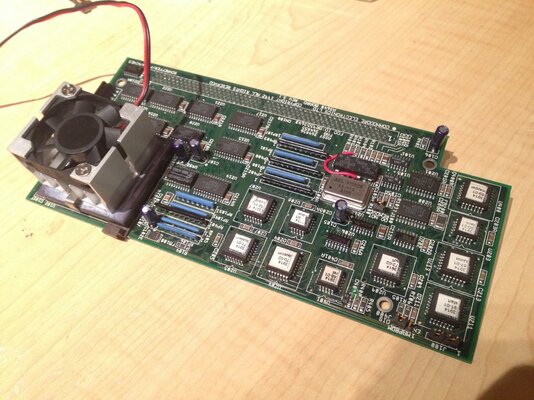

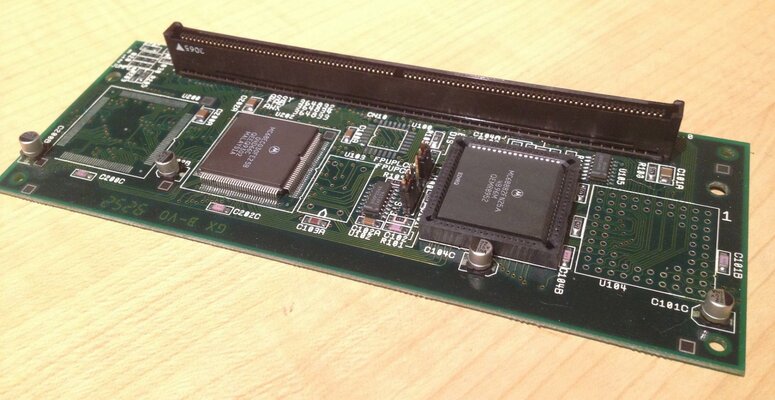

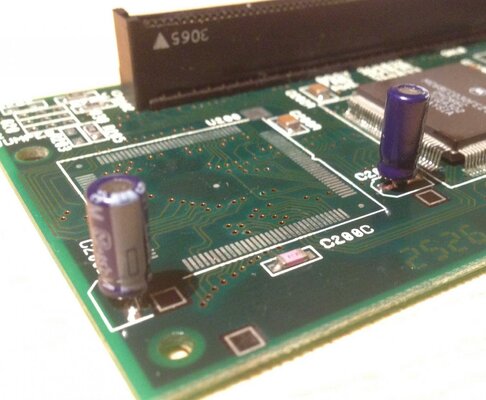

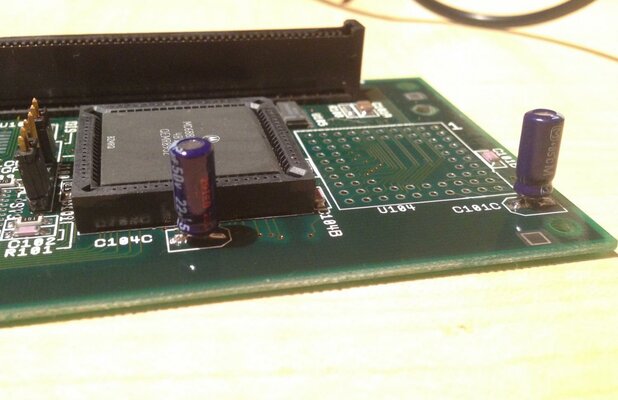

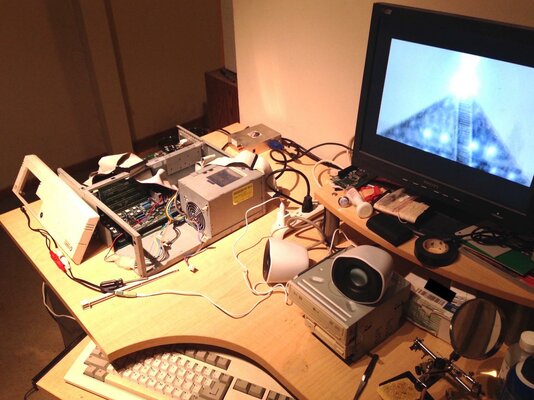

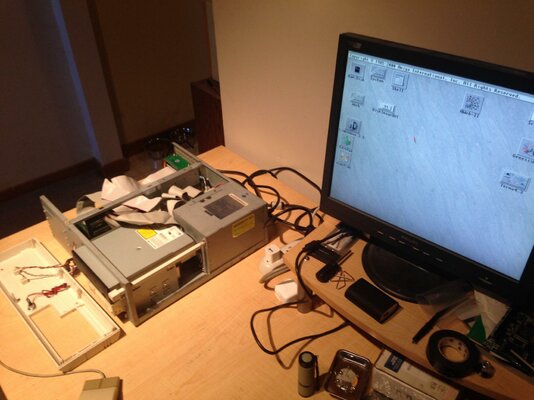

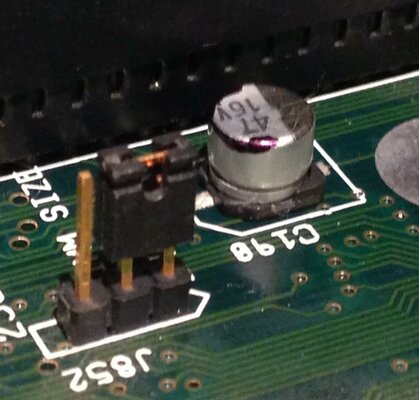

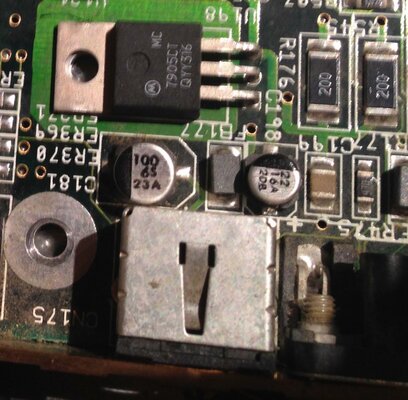

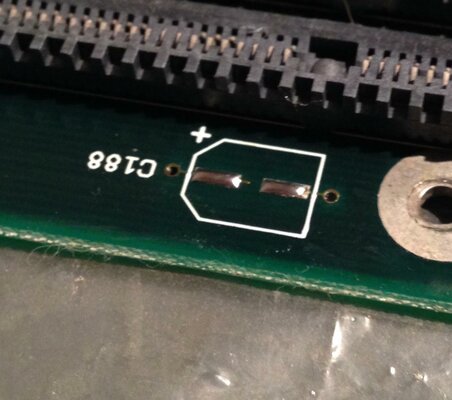

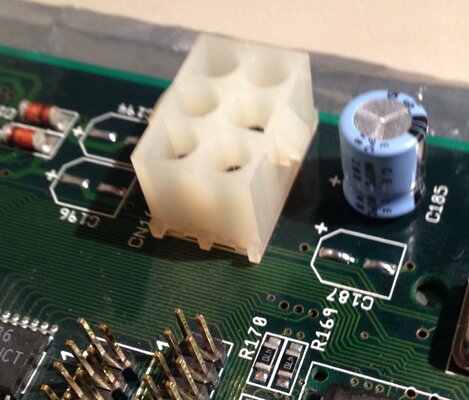

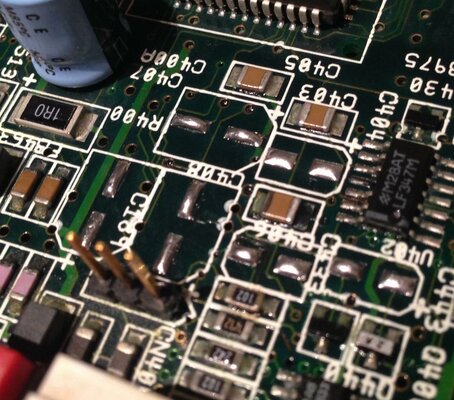

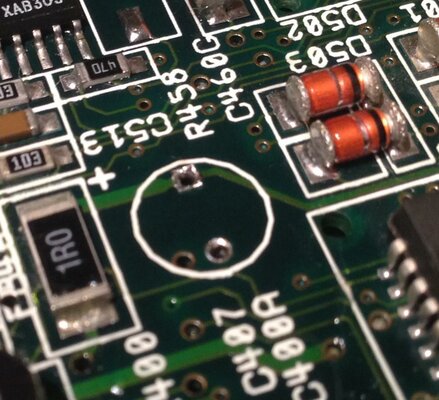

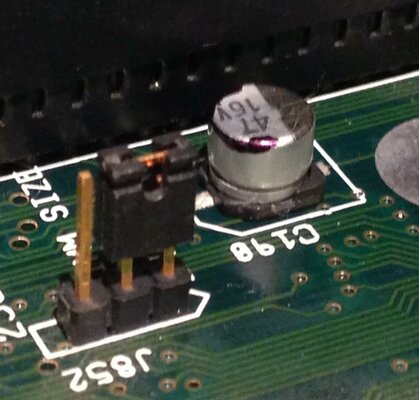

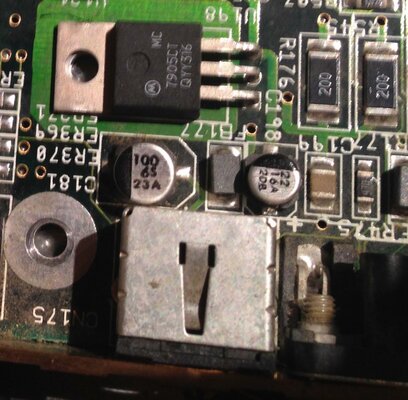

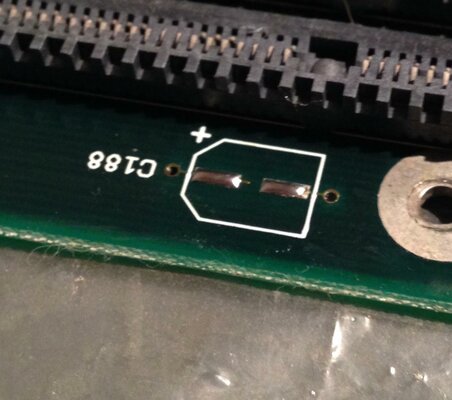

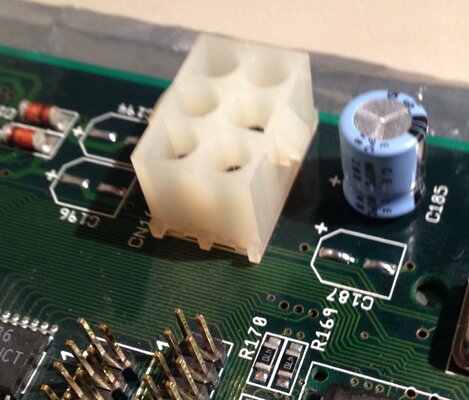

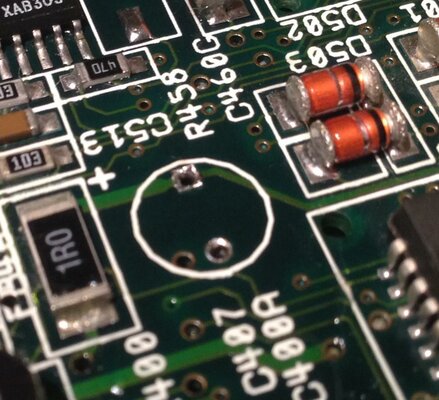

Here's a few pre-removal inspection shots:

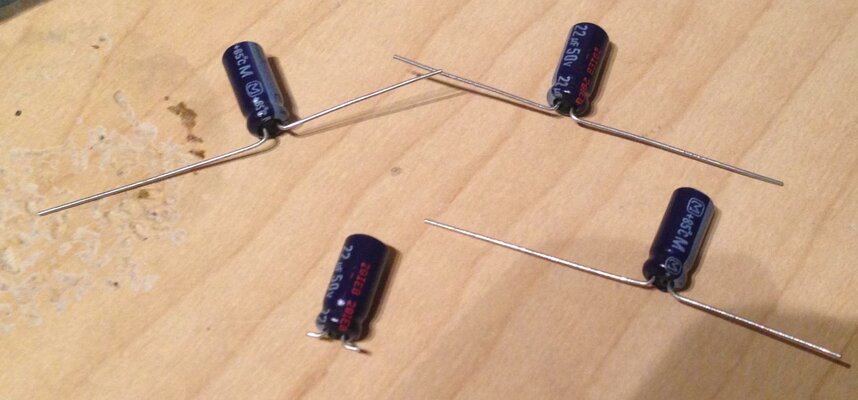

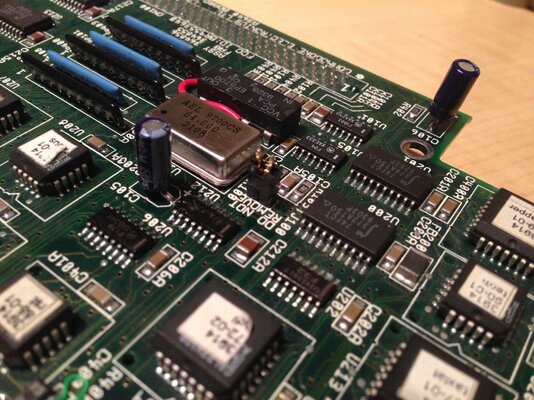

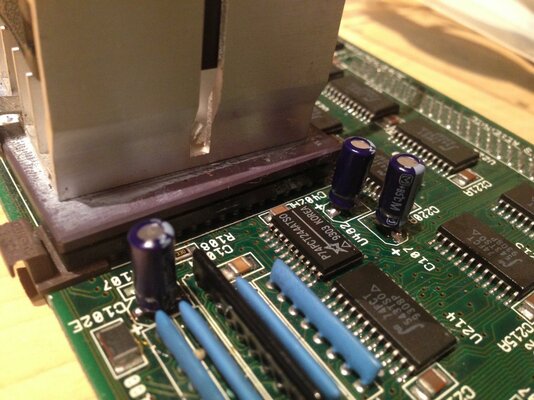

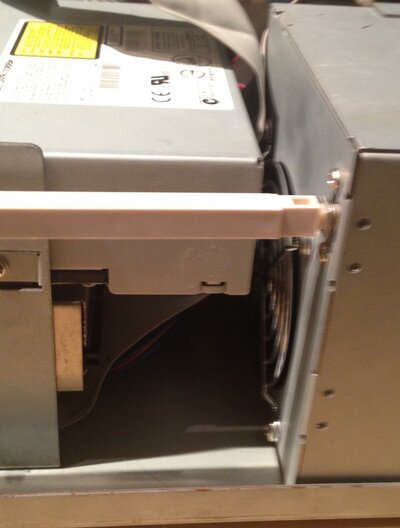

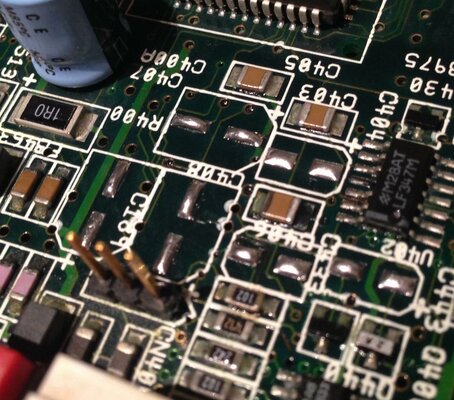

The removal technique I found the most effective but time-consuming (though somewhat therapeutic) was to apply gentle pressure and rock the cap back and forth until it loosens a bit then start rocking in alternating circular motion and after awhile it will fall off without much fuss. The through-hole caps can be removed in a similar fashion though just rocking them back and forth is usually enough. After that I hit them with flux, re-flow some solder to remove the old capacitor legs then clean them up and re-flow some new solder to the pads:

Up next; with the board all clean it's time to replace the caps.

I researched my options and decided I really wanted to fix it myself, but knew I wasn't skilled enough to do it as my work had been limited to large through-hole and wiring. I wasn't willing to risk it as this is my childhood machine that I'd used for 3D animation, code and music for many years growing up and has a lot of sentimental value.

So I set off to watch YouTube tutorials and try to learn everything I was missing. Off and on for the past few years I've been buying and soldering random kits and watching as many videos as I could to try and reproduce the techniques properly. In particular I found inspiration with the work of Dave Jones (EEVBlog), Louis Rossman (Flux The Everything!), Big Clive and many amiga-specific soldering demonstrations.

A few days ago I was more than confident that I was ready to tackle the A4000; upon opening the case for the first time in a few years it was quickly evident that nearly every cap had leaked -- in particular all the 47uf caps were sitting in a pool of their own electrolytes; so I quickly swabbed everything up with alcohol and prepared to extract them all.

Here's a few pre-removal inspection shots:

The removal technique I found the most effective but time-consuming (though somewhat therapeutic) was to apply gentle pressure and rock the cap back and forth until it loosens a bit then start rocking in alternating circular motion and after awhile it will fall off without much fuss. The through-hole caps can be removed in a similar fashion though just rocking them back and forth is usually enough. After that I hit them with flux, re-flow some solder to remove the old capacitor legs then clean them up and re-flow some new solder to the pads:

Up next; with the board all clean it's time to replace the caps.