Next up on this project then is to turn my attention to the case.

The original pictured earlier in the thread was in good shape overall, but not *quite* where I wanted it to be for the perfect job. I admit to being a perfectionist in a lot of areas; I dont see that as a bad thing either.

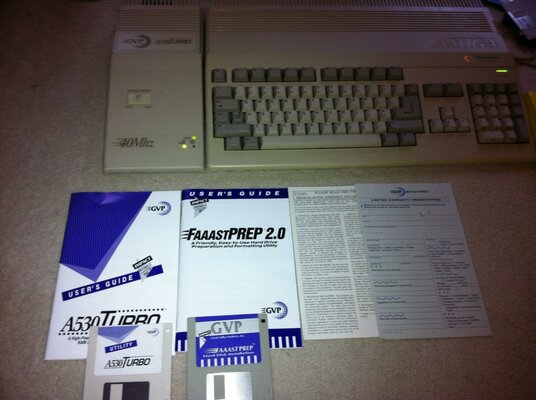

So, next was an order placed here on the forums through user GVP_SALES. Earlier this year he posted a sales thread offering brand new NOS A530 covers. That was a real stroke of luck then!

I sent for a box of GVP bits and pieces from him, including one of these covers.

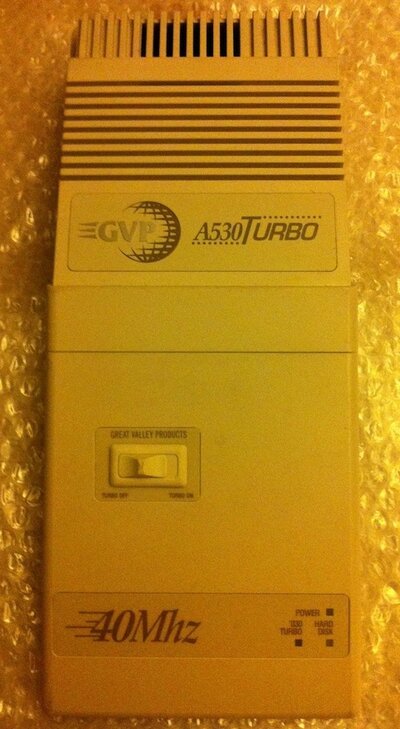

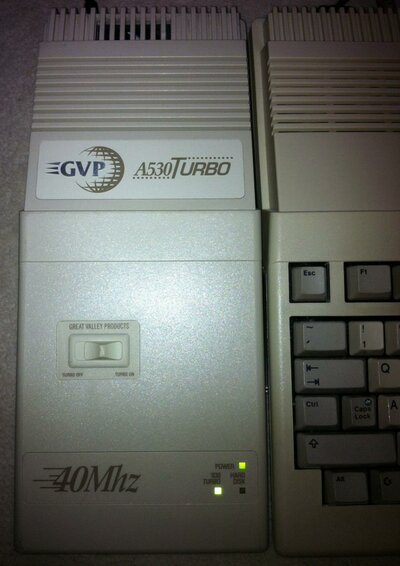

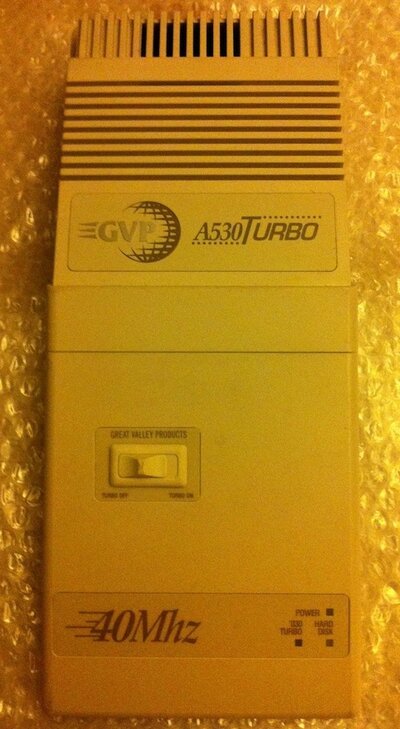

So, first off the new cover. Once again, the light levels are not perfect; the cover is spot on though :

And underneath. Obviously here you can see the cooling fan (more on than in a bit) and the wire connector for the Turbo Switch. This basically switches the expansion of the unit off or on :

Now, although the cover is NOS and in great condition, the fan has always been an issue for me. The existing ones are 15-20 years old, and while I would say they are adequate in what they do, Im going to do better. They were good for the standards back in the day of course.

The existing fan is a 12v 2-wire unit. Its noticeable in terms of noise but not excessive. The amount of air it shifts is questionable in my mind, so time to find a better option.

To the rescue this time then is a company called Fractal Design. You may be aware of them as a company that makes some very nice PC cases; I have one here for my main PC and its a super piece of kit.

But they also make power supplys, fans and other bits of kit too. I highly recommend the products from this company; they have good reviews and I have used their kit. It is good quality stuff.

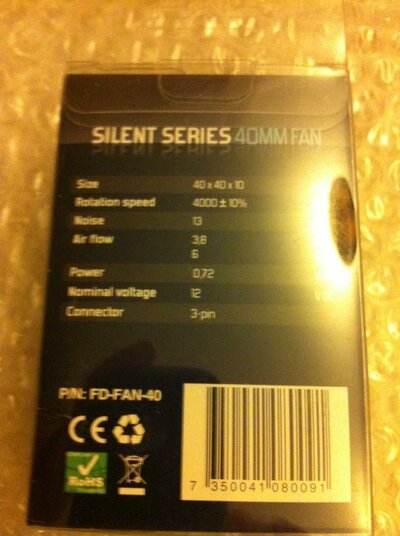

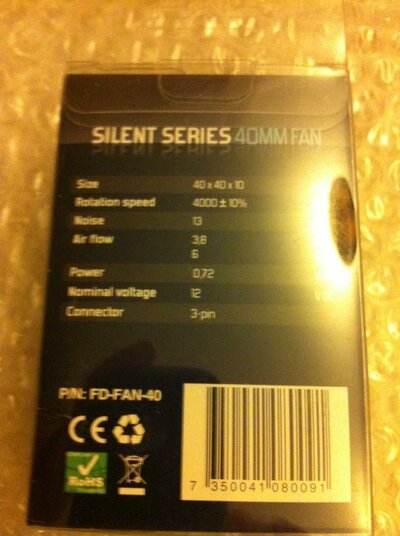

So, next up is a replacement fan. This is from their 'Silent Series' line and is a 40mm unit same as the existing one :

Even the packaging is good quality too. On the back we can see the technical details :

The essential details we need to know are :

Size : 40mm (Same as the existing one) and 10mm thick. The existing one is around 20-25 mm thick, so this will give us extra room to play with inside the case.

Rotational speed : 4000 rpm. Now this is quite high and from experience I often associate high speed and small size as 'screamers'. The kind of fan you got on your motherboard chipset and the like many years ago. They did a good job, but were anything but quiet.

But look at this :

Noise level : 13 dB. Yep thats right, just 13 decibels. Not bad at all for 4000 rpm. When choosing a fan its not only the decibel measurement thats important, but this is one of the key factors. 13 decibels at 4000 rpm is a great piece of engineering i reckon and perfect for what we want here.

Air flow : 3.8 CFM. This is more than adequate for the amount of air to be shifted though this unit. It doesnt require massive cooling efforts anyway; the processors run warm but not excessively hot. With the extra clearance we have inside due to the smaller fan and smaller disk unit, this should give us a good steady airflow.

Power requirement : 0.72 watts. Nice and low power requirement then, this wont tax our power supply at all; although its not a big issue even if it did due to the reworked PSU as detailed above.

Voltage : 12v. This is the same as the existing one.

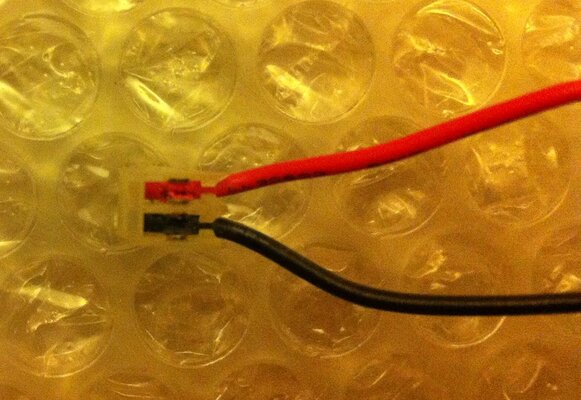

Connector : 3 pin. Hmm, the existing one is a 2 pin.No real issue here though; we have the 2 power supply wires and the third wire (Yellow) is actually a sensing wire that reports the fan speed. We simply wont connect this.

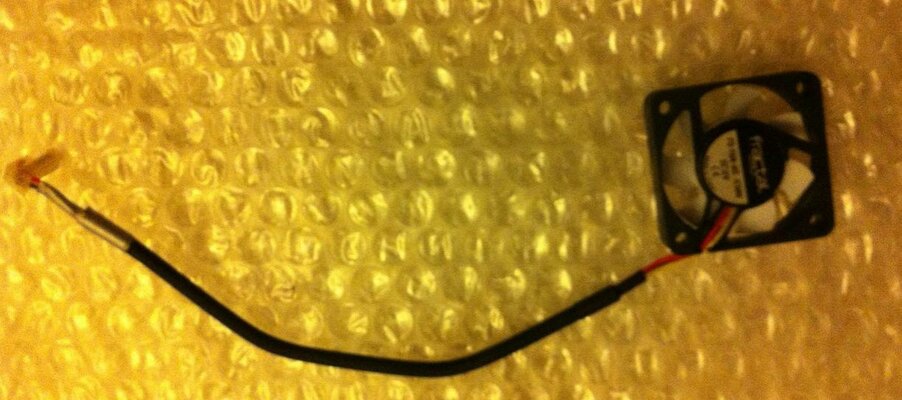

So here we have the fan up close and personal :

Notice the braided cover on the wiring; always a good sign of quality.

And the other side :

There are 2 options to fit this; I can either plug the existing connector over the power pins on the PCB just using the black/red wires in the connector, or I can cut the existing plug off the fan, snip the yellow wire and then connect just the red/black to the existing pins. This will also allow me to reduce the length of the wiring which is a bit on the long side for this job.

I dont have any glue to fit the fan to the cover yet, so that job will be completed shortly together with the wiring.

Stay tuned all !