Ok so a small update here, finally !

I wouldnt have taken this long except for a problem with a company I have dealt with (Until now that is).

The baseplate on this has been off to a 'professional' company to be worked on. The original idea was for it to be chemically cleaned and then chrome plated which would give it a real professional look.

In this case it turned out that wasnt possible. Throughout the life of GVP they supplied these base plates made of several different materials. Some were steel, some were aluminium and some were an aluminium alloy of some kind.

It turns out in this case that the baseplate is made of aluminium; what that means is that it can not be chrome plated as the chrome just wont stick to the aluminium.

Having spoken to the guy responsible several times, we settled with going for a clean and buff. This has gone well to a degree; but the issue with this kind of finish is that the surface is very vulnerable to scratches and smudging as it is not very hardy. He told me on the phone that the process had gone well and that it looked almost as good as chrome plating.

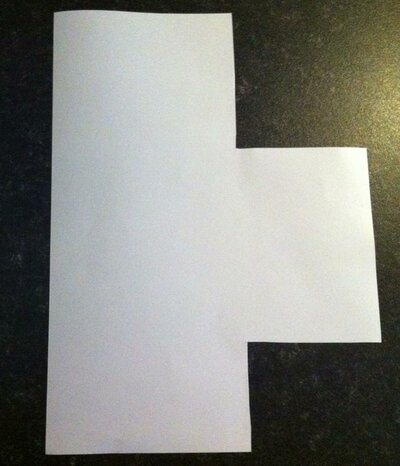

On to the pics then; this first one shows the bottom of the baseplate with its nice shiny finish, not a bad result overall :

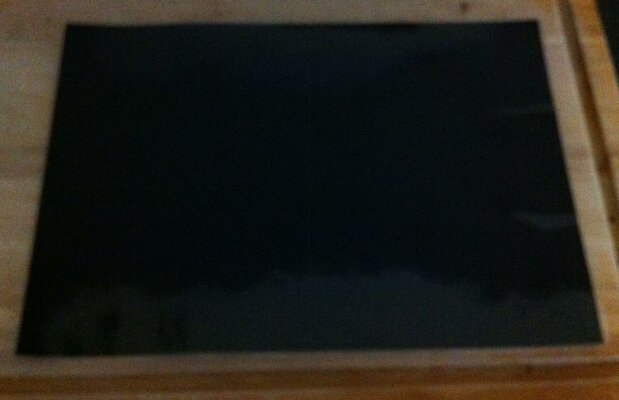

When I turned it over and looked inside I was very disappointed though :

He had left it covered in some kind of residue, presumably from the polishing material they use, and had made no effort on it whatsoever. You can see the patch where i cleaned a bit of it to show the difference.

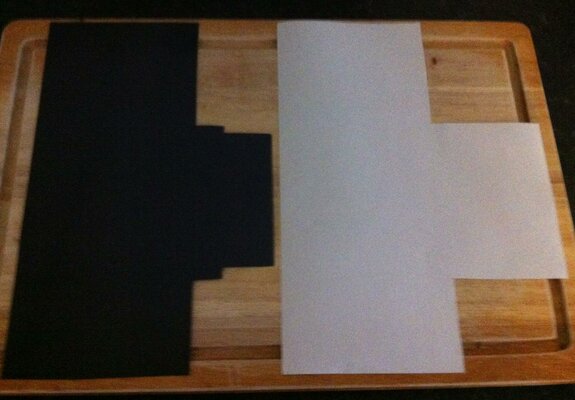

Next up I set about cleaning the inside as best I could by first of all getting rid of that residue :

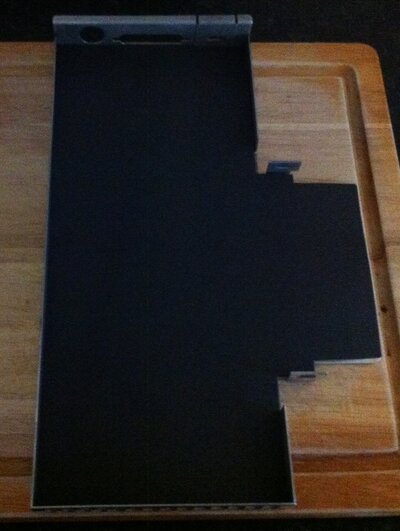

And finally giving it a polish by hand with some wadding polish (Silvo) :

I reckon thats about as clean as it will go. The guy who did the polishing should have done the inside the same as the outside but didnt; it was also with that company for several months. I reckon the work done on this took no more than an hour or so, hence I will not be using that company ever again.

Still, the overall result is good enough and its enough to proceed.

I wouldnt have taken this long except for a problem with a company I have dealt with (Until now that is).

The baseplate on this has been off to a 'professional' company to be worked on. The original idea was for it to be chemically cleaned and then chrome plated which would give it a real professional look.

In this case it turned out that wasnt possible. Throughout the life of GVP they supplied these base plates made of several different materials. Some were steel, some were aluminium and some were an aluminium alloy of some kind.

It turns out in this case that the baseplate is made of aluminium; what that means is that it can not be chrome plated as the chrome just wont stick to the aluminium.

Having spoken to the guy responsible several times, we settled with going for a clean and buff. This has gone well to a degree; but the issue with this kind of finish is that the surface is very vulnerable to scratches and smudging as it is not very hardy. He told me on the phone that the process had gone well and that it looked almost as good as chrome plating.

On to the pics then; this first one shows the bottom of the baseplate with its nice shiny finish, not a bad result overall :

When I turned it over and looked inside I was very disappointed though :

He had left it covered in some kind of residue, presumably from the polishing material they use, and had made no effort on it whatsoever. You can see the patch where i cleaned a bit of it to show the difference.

Next up I set about cleaning the inside as best I could by first of all getting rid of that residue :

And finally giving it a polish by hand with some wadding polish (Silvo) :

I reckon thats about as clean as it will go. The guy who did the polishing should have done the inside the same as the outside but didnt; it was also with that company for several months. I reckon the work done on this took no more than an hour or so, hence I will not be using that company ever again.

Still, the overall result is good enough and its enough to proceed.