I have a couple of small Arc-TIG welding inverters that are in need of repair. I'm not that clued up on these things, but I know that dangerous voltages and current lurk inside for the unwary. Is there anyone on here whose brain I can pick about repairing these machines?

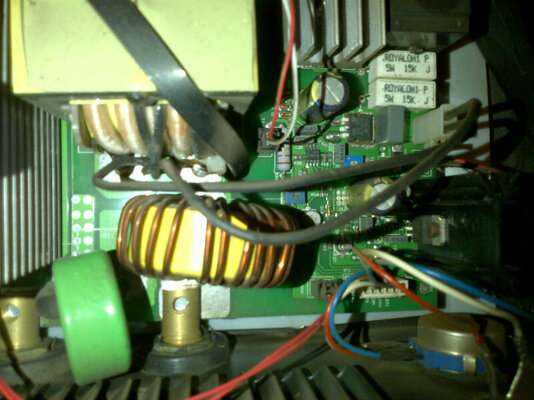

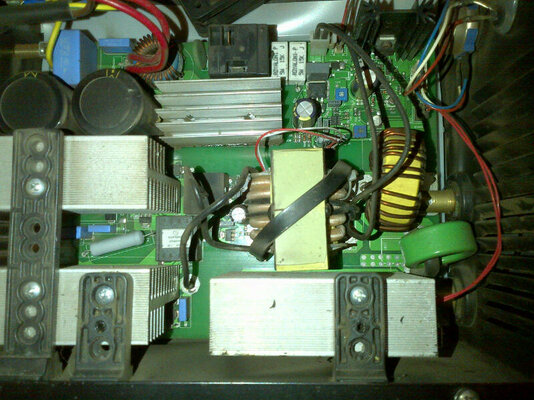

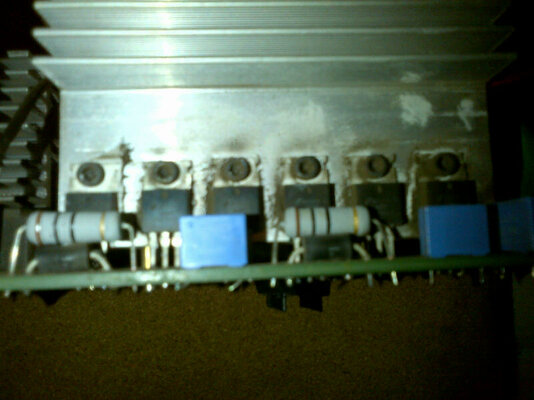

One is a Clarke AT150 Arc-Tig, the other is a Turkish make, a Kilmak Fantom 165. The Clarke is only putting out about 5 volts DC at the moment on the output side, but the internal cooling fan is running. The Kilmak is putting out about 28 volts DC, but the fan isn't working and the temperature warning LED is always on. They both work after a fashion, but they both need to be repaired.

Help, anyone?

One is a Clarke AT150 Arc-Tig, the other is a Turkish make, a Kilmak Fantom 165. The Clarke is only putting out about 5 volts DC at the moment on the output side, but the internal cooling fan is running. The Kilmak is putting out about 28 volts DC, but the fan isn't working and the temperature warning LED is always on. They both work after a fashion, but they both need to be repaired.

Help, anyone?