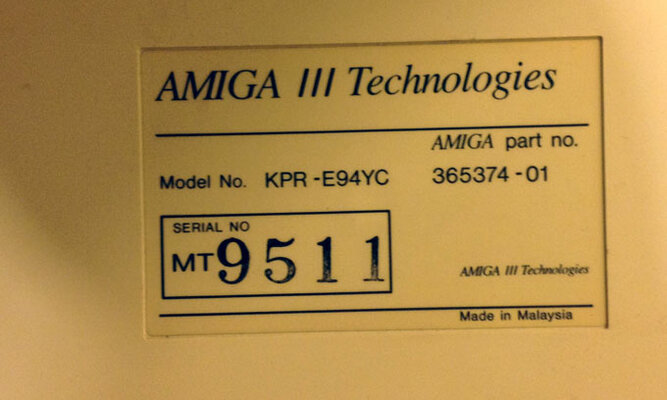

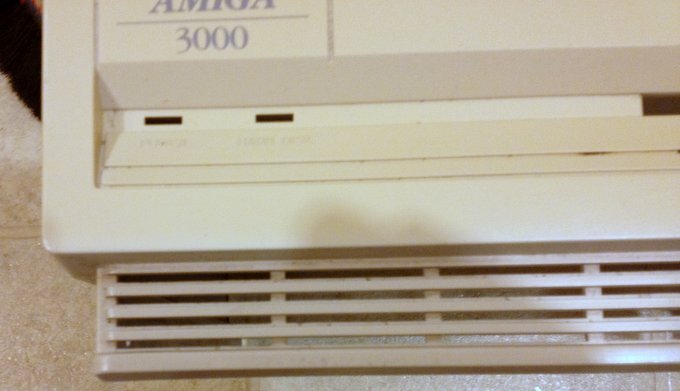

Day 9

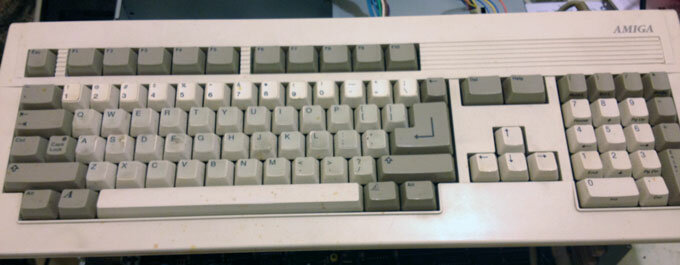

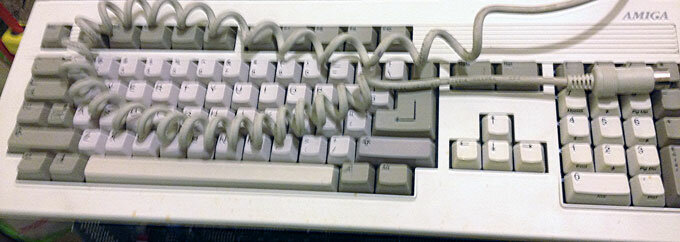

Today, I spent a lot more time then I normally do on this keyboard!

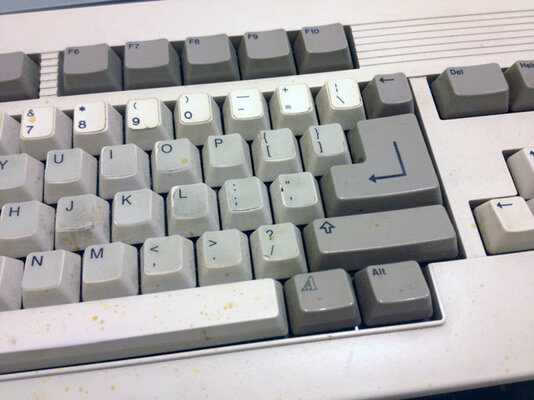

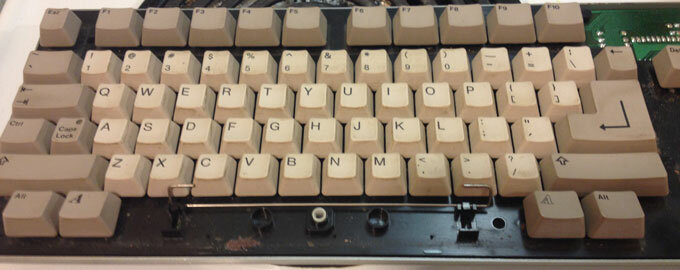

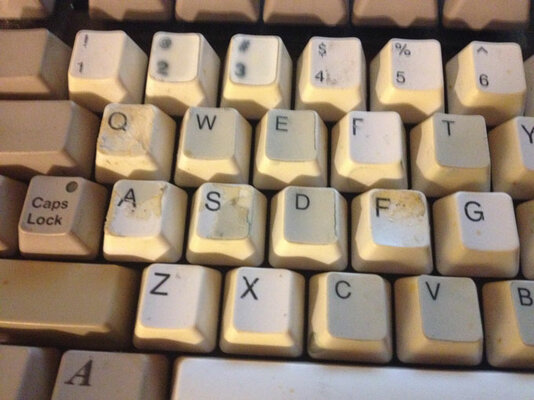

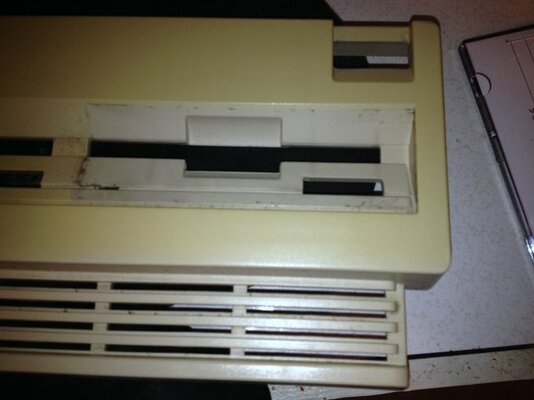

I first vacuumed off the dust, hair, and general grime off of the keyboard. It looked good except for this small area above the space bar. I thought it was just dried coke or some kind of syrupy substance, so I got to scrubbing with a toothbrush. After about 5 min, I decided to switch from Windex to hot water for this, after all, what better than hot water to dissolve sugar lumps. I got a small pan of water boiling on the stove and kept sticking the toothbrush in it. Nothing was giving, so then I switched to a small fine steel brush. This just ended up scratching and gouging the plastic. Try as I might, this “stuff” was not going to give.

I then washed down the rest of the board with Windex.

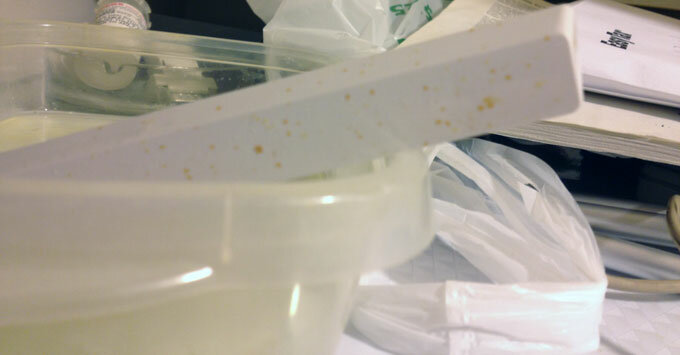

Now, comes the tedious part, the scrubbing and replacing of the keys. Since the space bar was so spotted up, I let that soak in a bath of bleach overnight. I took out the bar, and discovered the bleach had did nothing. I then gave it a good scrub, and discovered the brown marks were not going to come off.

At this time, a small theory was starting to form in my head about the brown spots, key-stickers and the piles of stuff (that I thought was sugar) under the keys. (but I will get to that hypothesis later).

I then put netflix “House Of Cards” on for background, and began the long task of peeling stickers off, scrubbing, and replacing keys.

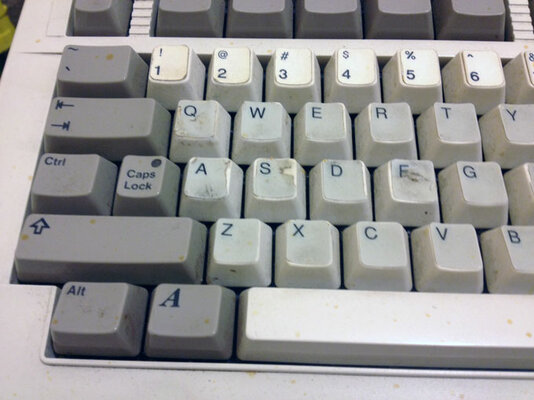

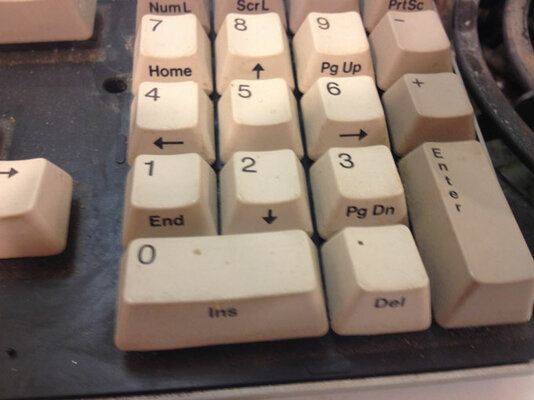

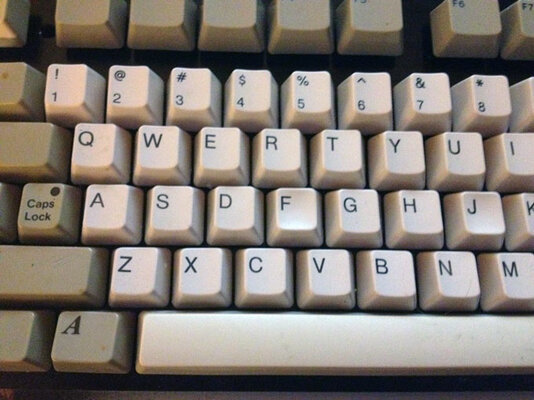

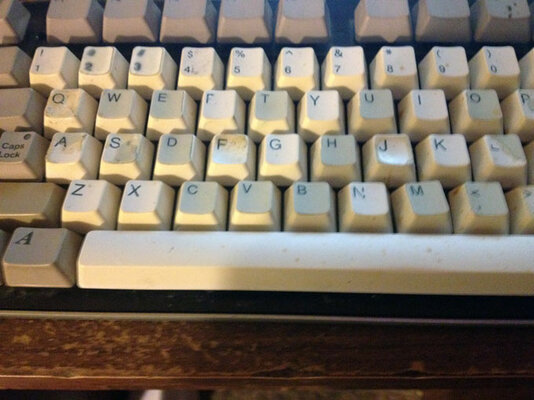

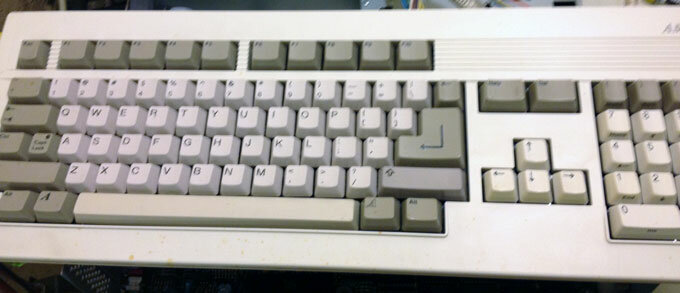

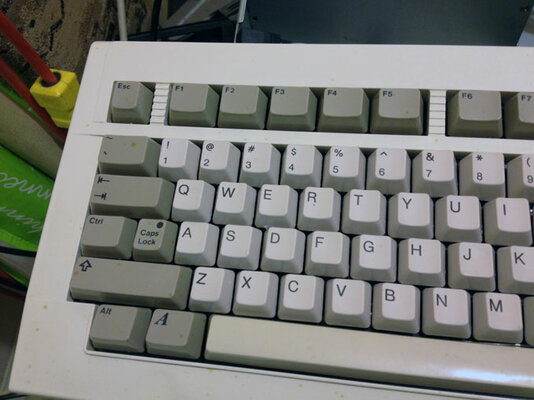

It wasn't long before I began to notice a few things, first, the white keys showed signs of UV yellowing on the sides. The brown spots were everywhere, and once I began to peel off the stickers, I could see that about 60% of the keys were “losing” the actual letter (it was coming off). Finally, a bunch had scratches or gouges in them.

I began tossing aside the keys that were really bad, thinking I would replace them from my donar keyboard later.

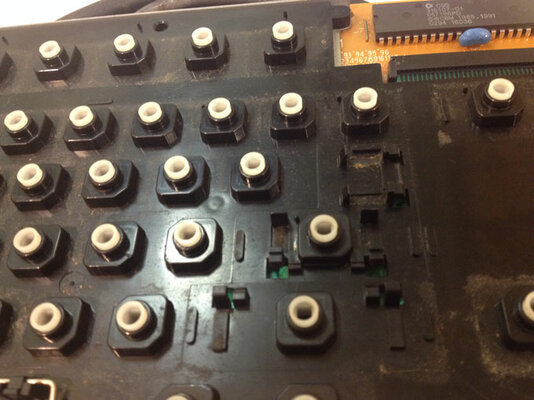

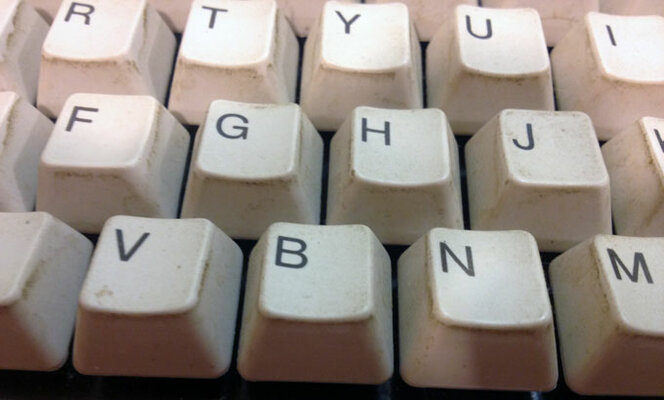

About a hour in I came across keys that had the stickers re-glued with crazy glue or such. This was the “B” key, and right were that big pile of gunk was. So, (I guess) the big pile of gunk was actually hardened glue and I could of scrubbed til the cows came home and got nowhere.

So, my theory is this. The brown spots were wood stain. Probably splattered accidentally or they forgot to cover the keyboard when painting. They then tried to remove the brown spots with paint thinner, and thus, started to remove the ink off the keys as well. Then they got the stickers, to try to cover the damage they had done. Sometime later, a few of the stickers had started to come loose and they glued them back on, but some of the glue dripped down between the keys, mixing with the grime underneath.

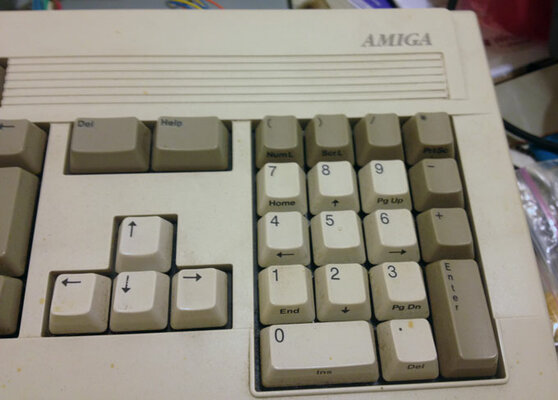

So, about an hour or so in I then decided to replace all the white letter keys from my donor board. I then removed the ones I had and got to work popping the keys off the donor board. The other keys are more grey then white, but at least it will look nicer.

I wanted to let those keys soak overnight also, but I wanted to “test” one out. It was then I found out that even though they look almost Identical, the locking mechanism is a tad smaller in the donor board. Meaning, I will also have to swap out the slides inside. This will require a bunch more work, but I think it will be well worth it in the end.

I will leave that for the next days chore.