Hi all,

Well its time for some more A530 restoration goodness!

I recently acquired this unit here on the forums and I'm quite pleased with her overall.

I previously carried out a restoration on one of these units; details can be seen here :

https://www.amibay.com/showthread.php?t=29435

That went very well, if a little slowly, but these things can not be rushed.

The process this time will have some differences though. Things I have learnt from the original process, other information I have come across since then. Some will be done the same, some will be done differently. The ultimate aim though will be the same; that is a fully restored unit in pristine condition !

So I'll dig straight into the pics and initial observations then

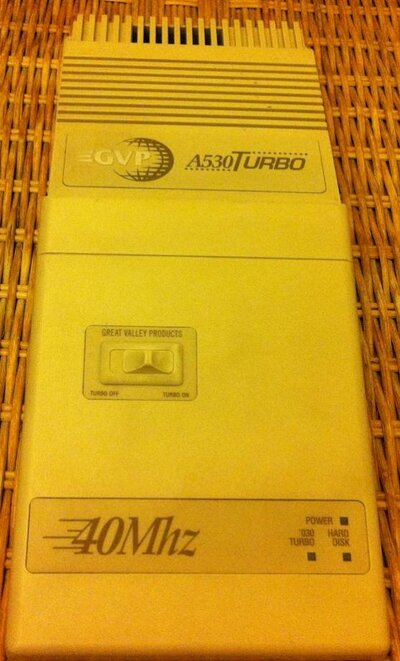

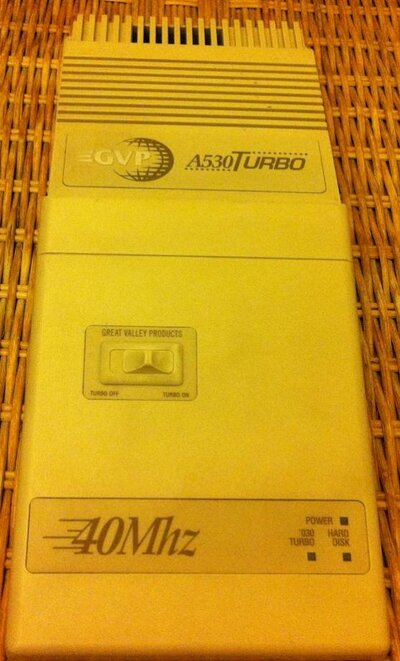

First up is the cover; this is a tad on the grubby side, but in fair condition overall :

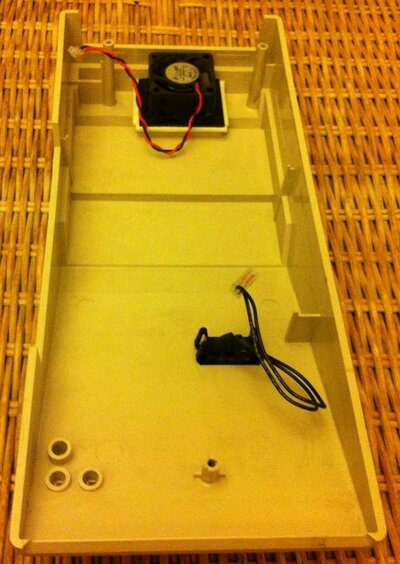

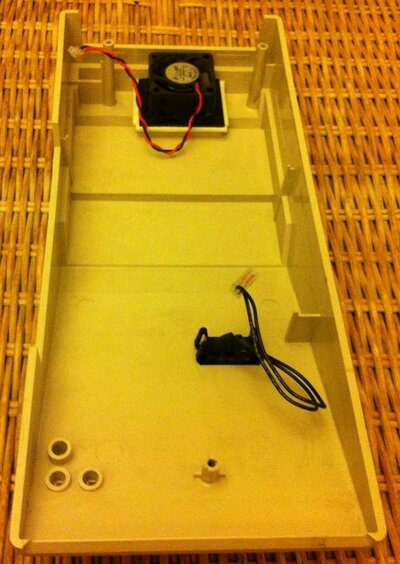

Inside she looks ok, but there is an issue with the screw posts. The screws for the cover have previously been removed and replaced several times and the screws seemingly over-tightened. Now when we attach those screws, they just spin as the posts have started to split. This happens easily with these GVP units; here we go underneath the cover :

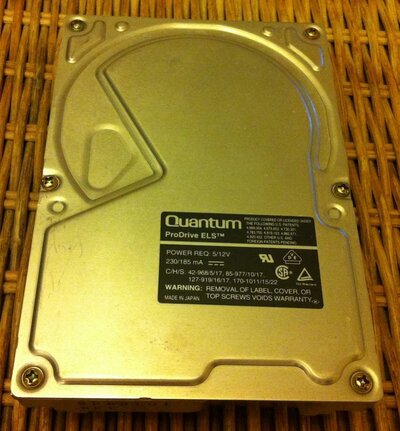

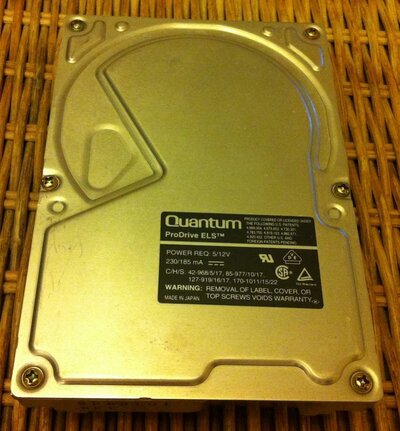

Next up the existing HDD. No surprises here; the unit is a Quantum ProDrive ELS 50Mb, one of three very common units that were supplied by GVP back in the day :

And underneath :

As before, the unit is years old. It is fully working, somewhat noisy, and draws a fair amount of power.

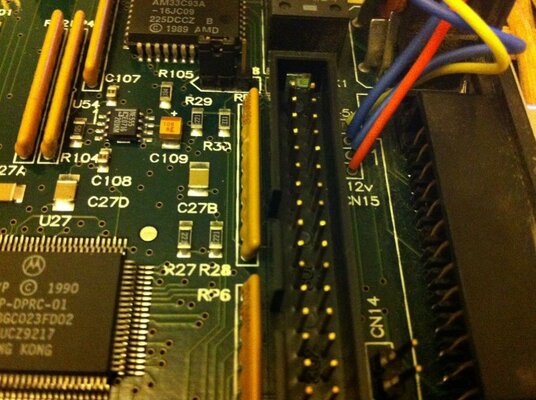

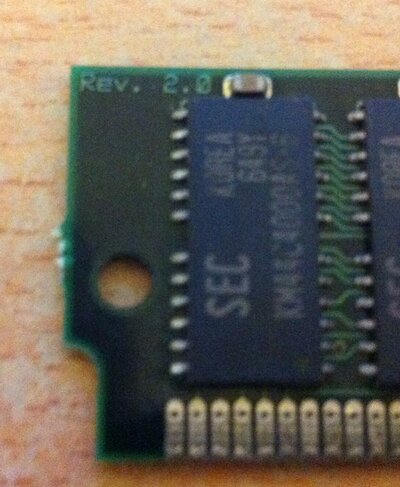

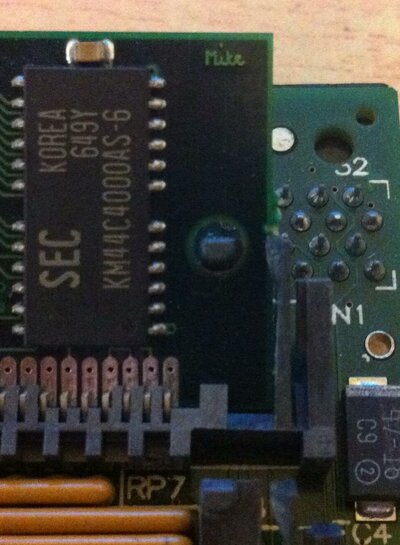

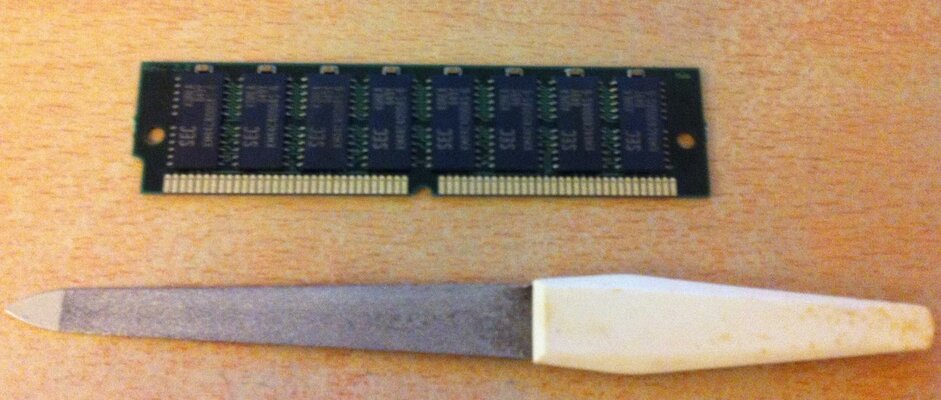

Now we have the main pcb itself. The basic signs here are good. No internal damage or broken components, all the chips appear in good shape and the memory sockets are 100% too. If the memory sockets go on these things there is not a lot you can do since they are proprietory units. These ones are in good shape though :

Underside of the main pcb we can see she is in good shape too. All tracks intact, no damage, no scratches or anything :

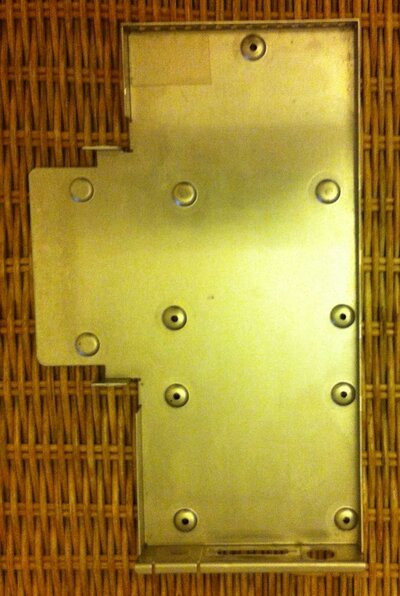

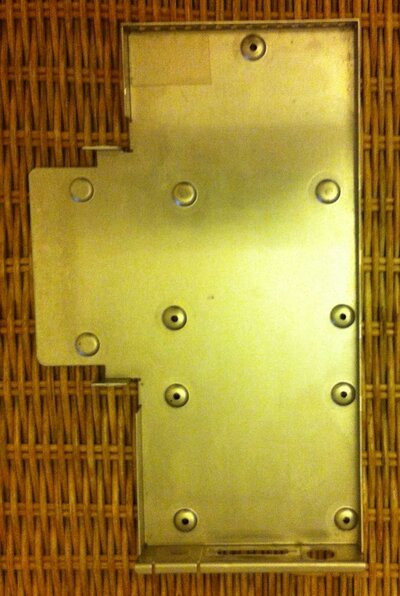

On to the baseplate. This is a variation of the GVP stuff I've come across before. Its a light aluminium plate in one piece. This one has no mounting holes for the pcb half way down which is usually typical of the A530 in particular. This one, without the additional mounting holes was usually used for the HD8 and HD8+ units, but thats ok. Also we can see the telltale plastic sticker in the corner. Im not sure why these were fitted, it doesnt appear to serve any purpose :

Underneath its nice and clean and we can see the remains of the metallic sticker; this defines the unit as an A530 (obviously!), but the sticker will be removed during this restoration process :

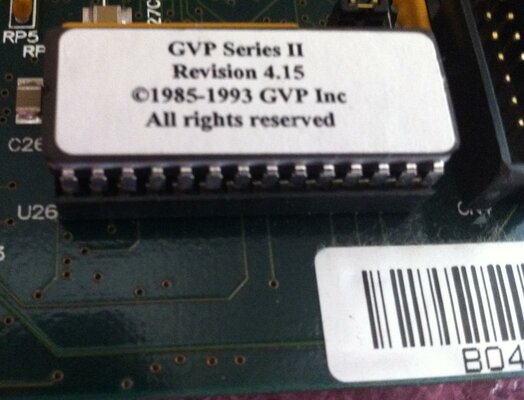

Looking closer at the pcb then, we have a more recent rom chip (4.15) which is available from one of our forum members here :

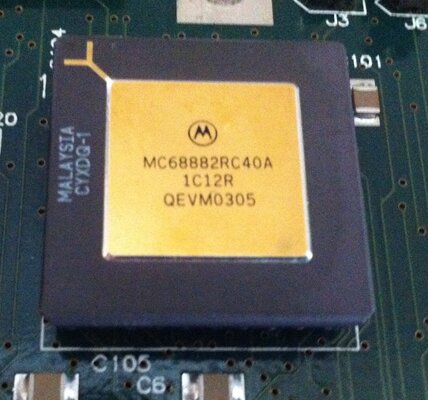

And looking across to the sockets; it is currently fitted with a 40mhz EC part CPU but no co-pro :

So already we have issues with the unit, but nothing which can not be fixed up.

The cpu will be replaced with a full fat version, a co-pro will be installed, the disk subsystem will be replaced and some other work will be carried out too.

More details to follow shortly

Well its time for some more A530 restoration goodness!

I recently acquired this unit here on the forums and I'm quite pleased with her overall.

I previously carried out a restoration on one of these units; details can be seen here :

https://www.amibay.com/showthread.php?t=29435

That went very well, if a little slowly, but these things can not be rushed.

The process this time will have some differences though. Things I have learnt from the original process, other information I have come across since then. Some will be done the same, some will be done differently. The ultimate aim though will be the same; that is a fully restored unit in pristine condition !

So I'll dig straight into the pics and initial observations then

First up is the cover; this is a tad on the grubby side, but in fair condition overall :

Inside she looks ok, but there is an issue with the screw posts. The screws for the cover have previously been removed and replaced several times and the screws seemingly over-tightened. Now when we attach those screws, they just spin as the posts have started to split. This happens easily with these GVP units; here we go underneath the cover :

Next up the existing HDD. No surprises here; the unit is a Quantum ProDrive ELS 50Mb, one of three very common units that were supplied by GVP back in the day :

And underneath :

As before, the unit is years old. It is fully working, somewhat noisy, and draws a fair amount of power.

Now we have the main pcb itself. The basic signs here are good. No internal damage or broken components, all the chips appear in good shape and the memory sockets are 100% too. If the memory sockets go on these things there is not a lot you can do since they are proprietory units. These ones are in good shape though :

Underside of the main pcb we can see she is in good shape too. All tracks intact, no damage, no scratches or anything :

On to the baseplate. This is a variation of the GVP stuff I've come across before. Its a light aluminium plate in one piece. This one has no mounting holes for the pcb half way down which is usually typical of the A530 in particular. This one, without the additional mounting holes was usually used for the HD8 and HD8+ units, but thats ok. Also we can see the telltale plastic sticker in the corner. Im not sure why these were fitted, it doesnt appear to serve any purpose :

Underneath its nice and clean and we can see the remains of the metallic sticker; this defines the unit as an A530 (obviously!), but the sticker will be removed during this restoration process :

Looking closer at the pcb then, we have a more recent rom chip (4.15) which is available from one of our forum members here :

And looking across to the sockets; it is currently fitted with a 40mhz EC part CPU but no co-pro :

So already we have issues with the unit, but nothing which can not be fixed up.

The cpu will be replaced with a full fat version, a co-pro will be installed, the disk subsystem will be replaced and some other work will be carried out too.

More details to follow shortly

Last edited: