After re-capping my A4000 I inspected some of my other systems, the A600 was looking particularly leaky so it was next up for repair.

Instead of the "gentle mechanical removal" method from before, this time I decided to try using ChipQuik.

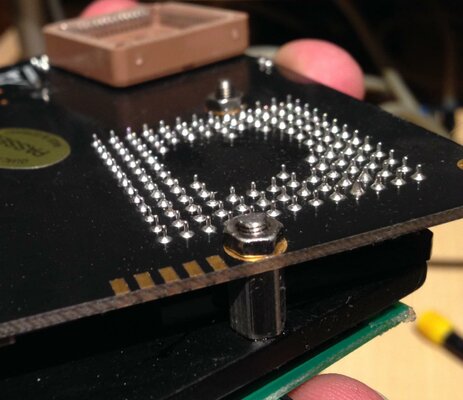

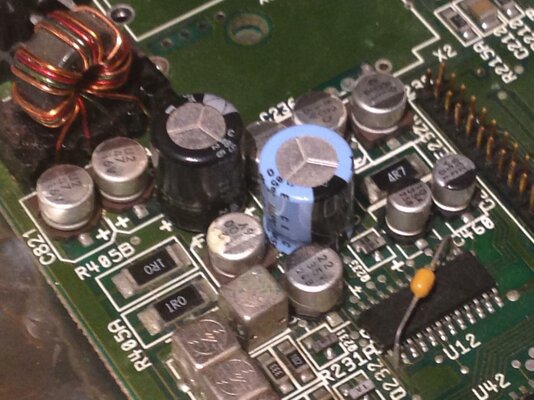

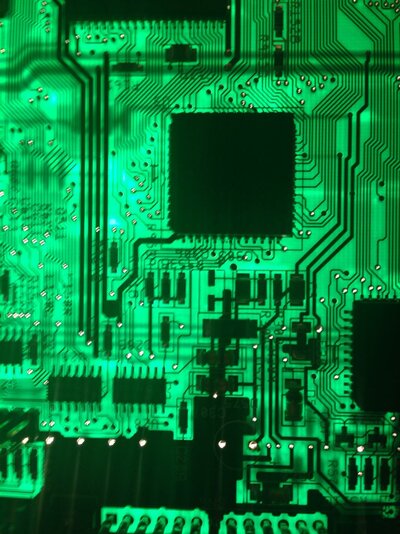

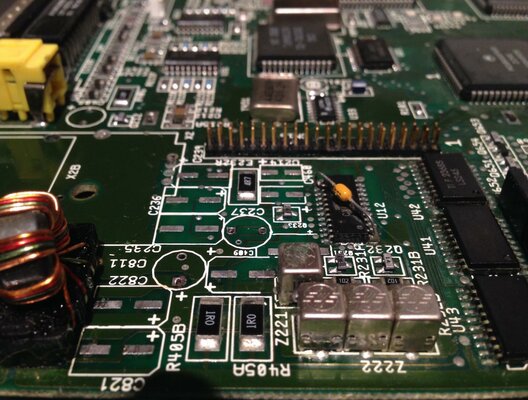

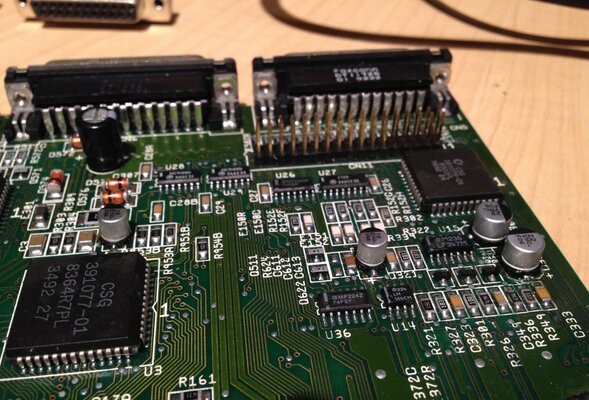

Taking a close look at the power input capacitors it's clear that most everything has leaked, plenty of dull or darkening leads, corrosion and residue:

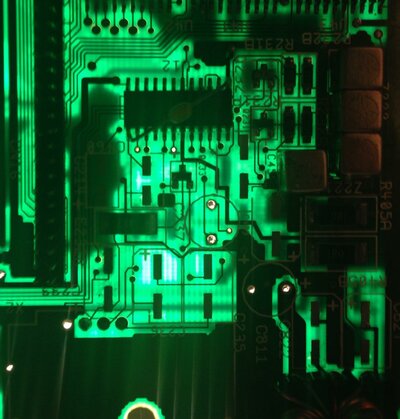

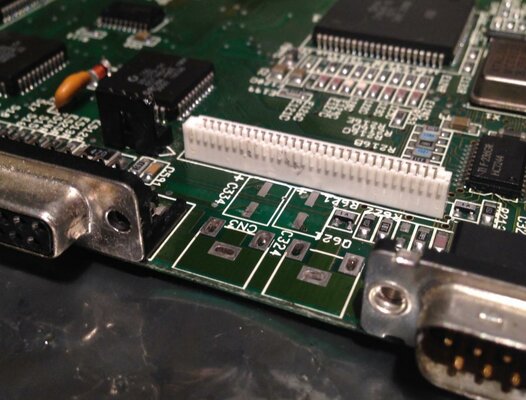

Others fared better, but still some corrosion on a capacitor known for causing timing problems and cloudy leads on the others:

ChipQuik usage was fairly straightforward; it's brittle so it's easy to brake off a small segment with tweezers and drop it in a blob of flux on each of the capacitor leads. Touch it with the iron for 2-3 seconds and it pulls itself into the old solder. After that you can re-heat quickly and have several seconds to remove the part easily.

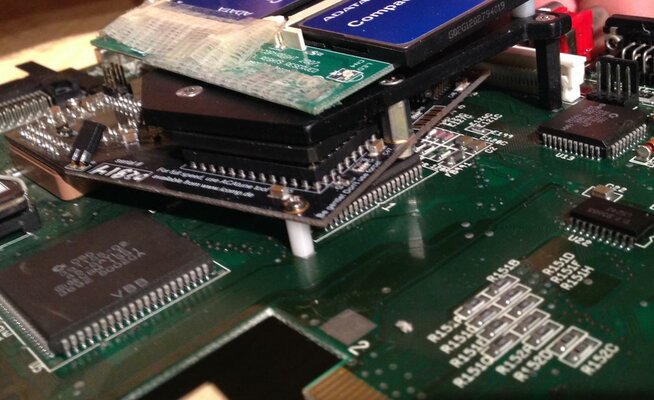

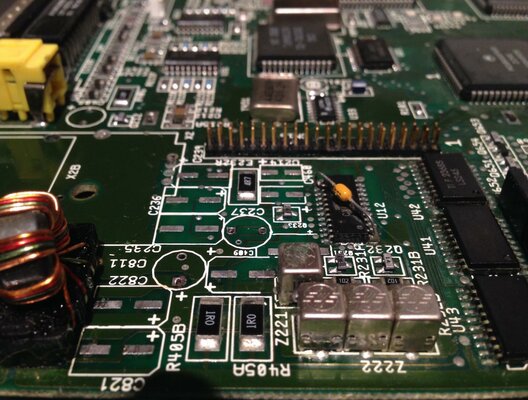

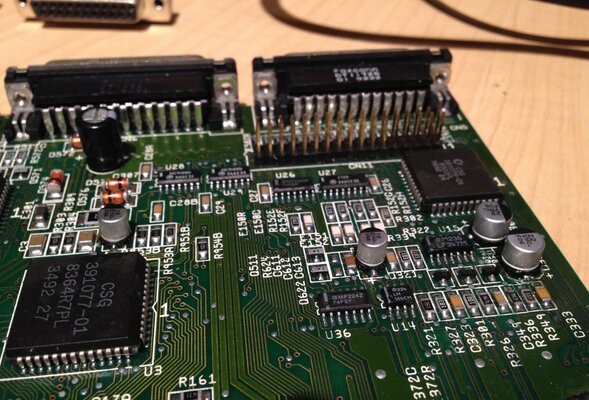

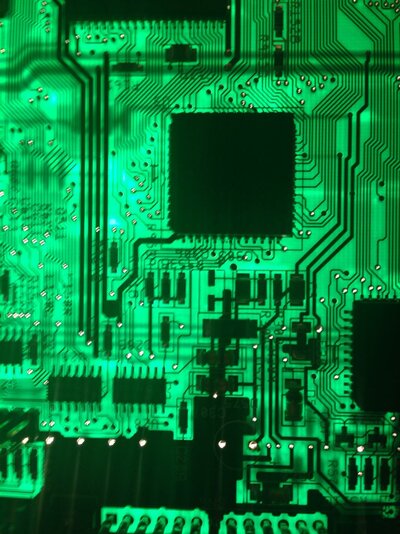

Here's the power input and audio areas de-capped and cleaned up -- cleaning just requires re-heating and wiping away with a bit of flux on a cotton swab while it's still molten for a few seconds:

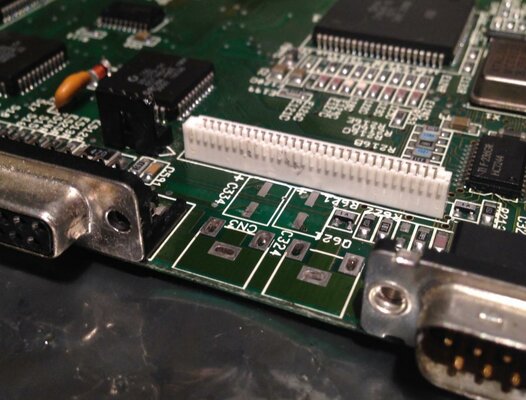

Inspecting the traces in the heavily corroded areas, all appears good:

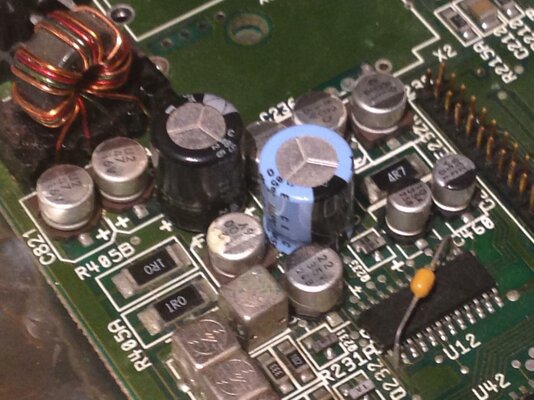

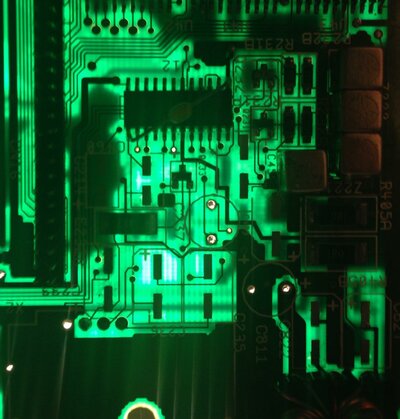

Capacitors replaced; put a bit too much solder on the pads + the iron tip and it bubbled out a bit when pressed down; a few have nice fillets but will definitely have to hold back on the solder a bit next time. All connections at least appear solid and measure sanely with the meter.

One of the pads in the power area had lifted with some corrosion underneath and I managed to snag it on a cotton swab while cleaning :hammer: -- Luckily the capacitor and it's neighbour just lead to a dead end where the RF modulator used to be..

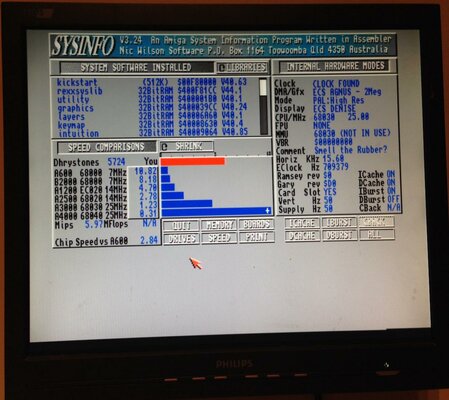

The project was shelved for a bit while waiting for parts; but by the time I was ready to give it a try, testing my power bricks revealed I didn't have a single functional supply..

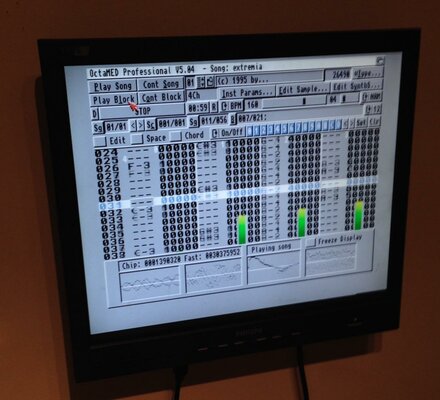

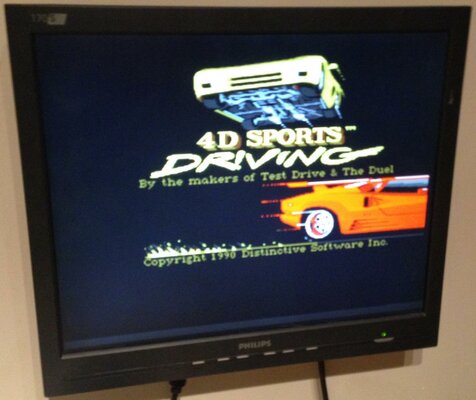

Then recently I tried to build a new one from an ATX supply which was successful! So next up; putting it back together and hoping it works

Instead of the "gentle mechanical removal" method from before, this time I decided to try using ChipQuik.

Taking a close look at the power input capacitors it's clear that most everything has leaked, plenty of dull or darkening leads, corrosion and residue:

Others fared better, but still some corrosion on a capacitor known for causing timing problems and cloudy leads on the others:

ChipQuik usage was fairly straightforward; it's brittle so it's easy to brake off a small segment with tweezers and drop it in a blob of flux on each of the capacitor leads. Touch it with the iron for 2-3 seconds and it pulls itself into the old solder. After that you can re-heat quickly and have several seconds to remove the part easily.

Here's the power input and audio areas de-capped and cleaned up -- cleaning just requires re-heating and wiping away with a bit of flux on a cotton swab while it's still molten for a few seconds:

Inspecting the traces in the heavily corroded areas, all appears good:

Capacitors replaced; put a bit too much solder on the pads + the iron tip and it bubbled out a bit when pressed down; a few have nice fillets but will definitely have to hold back on the solder a bit next time. All connections at least appear solid and measure sanely with the meter.

One of the pads in the power area had lifted with some corrosion underneath and I managed to snag it on a cotton swab while cleaning :hammer: -- Luckily the capacitor and it's neighbour just lead to a dead end where the RF modulator used to be..

The project was shelved for a bit while waiting for parts; but by the time I was ready to give it a try, testing my power bricks revealed I didn't have a single functional supply..

Then recently I tried to build a new one from an ATX supply which was successful! So next up; putting it back together and hoping it works

Last edited: