Hi all,

Been reading this forum a lot and get inspiration to get and upgrade Amiga 600 because of you! So decided to also post photos of my ongoing project just in case I need help but also perhaps somebody could get useful ideas and avoid mistakes I made...

So my goal is:

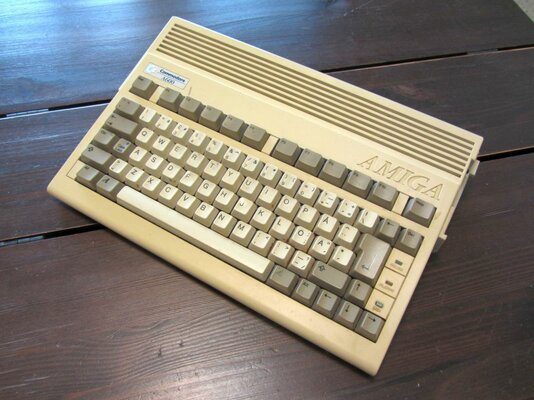

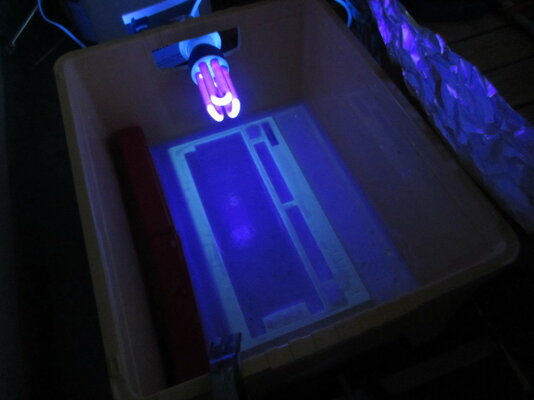

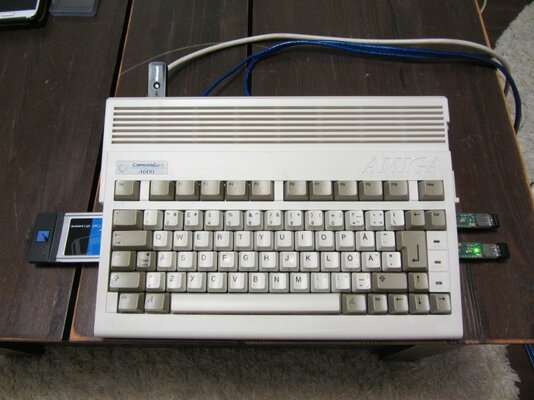

1) Buy used Amiga 600

2) Restore it as necessary including Retr0bright bath if necessary

3) Add accelerator and all necessary goodies

4) WHDload

I already was able to secure old Amiga 600 and started my project, pics will follow...

Edit: Oh and forgot 2.5) Re-cap motherboard and PSU.

-Jarp

Been reading this forum a lot and get inspiration to get and upgrade Amiga 600 because of you! So decided to also post photos of my ongoing project just in case I need help but also perhaps somebody could get useful ideas and avoid mistakes I made...

So my goal is:

1) Buy used Amiga 600

2) Restore it as necessary including Retr0bright bath if necessary

3) Add accelerator and all necessary goodies

4) WHDload

I already was able to secure old Amiga 600 and started my project, pics will follow...

Edit: Oh and forgot 2.5) Re-cap motherboard and PSU.

-Jarp

Last edited: